On the one hand, pressure-treated wood is among the most fitting materials for use in roof rafters due to its superior durability. One of the main concerns builders face when constructing roofs is the amount of moisture or water that will contact the wood. This is not a major worry with pressure-treated wood, as the timber is water-resistant.

On the other hand, the International Residential Code and International Building Code do not have provisions stipulating the mandatory use of pressure-treated lumber for structural components of roof assemblies.

So, which of the two points of view should you follow? Here is a guide to help you make the right choice.

Pressure Treated Wood

As noted in our outdoor wood treatment piece, wood is pressure treated by placing it into a hermetically sealed tank containing a mixture of chemical preservatives and hot water. These preservatives are infused into the lumber by increasing pressure inside the container.

This treatment can be an empty-cell or full-cell process. The latter involves a thorough preliminary vacuuming phase whereby all the air is ejected from the tank to ensure the wood absorbs and retains maximum liquid preservative. Inversely, in the empty-cell process, wood is first placed under air pressure and infused with preservatives. Here, the preservative is absorbed deeper but with a lower retention rate.

Preservatives Used for Pressure Treatment

There are three main preservatives used in pressure-treated wood. Waterborne preservatives are the most common. These chemicals are infused into the wood with water as their primary carrier medium and are mostly used in construction timber.

Secondly, due to their added structural support, oil-based preservatives are utilized in industrial timber, such as glulam beams and utility poles. Lastly, creosote preservatives include a mixture of tar and coal and are also used for heavyweight industrial applications.

What are Roof Rafters?

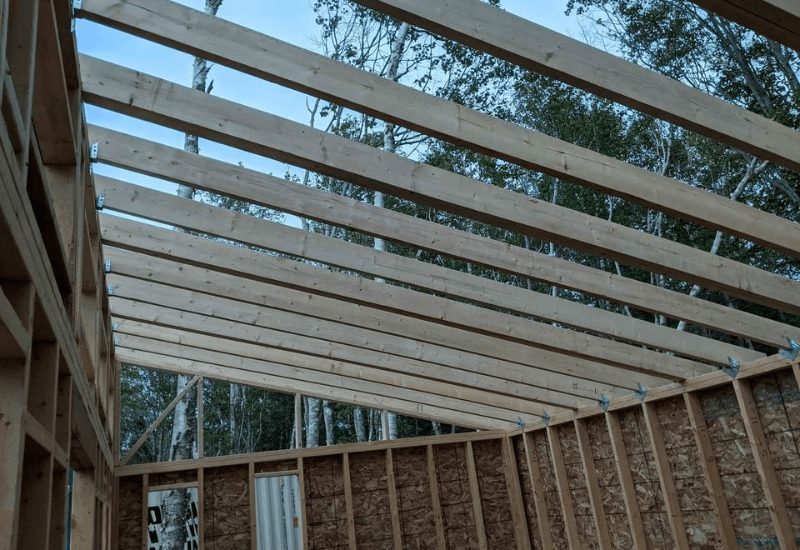

Roof rafters are structural components of a roof. They run from the roof’s hip, known as the ridge, to the outermost wall plate. These wooden structures are positioned side by side to ensure they provide ample base support for roof coverings and roof decks.

In a couple of roof designs, two rafters are placed against each other and joined at the ridge. It is similar to a closed couple roof design, but this structure has additional ceiling joints placed horizontally between the rafters for added support. Typically, rafters use 2×12, 2×8, and 2×10 wood sizes.

Difference between Rafters and Trusses

Most people use the terms rafters and trusses interchangeably. While both items are structural components of a roof, they differ greatly in design. While rafters are solely designed to offer structural support to the roof, trusses feature a triangular webbing that enables them to support the roof and hold a house’s walls in place. Moreover, trusses use smaller-sized timber, most notably 2x4s.

Can you use pressure-treated wood for roof rafters?

Yes. Although it is not mandatory, using pressure-treated wood for rafters adds to your building’s durability and rigidity. Such timber is more resistant to moisture, rot, and insect infestations than untreated wood. There is a good chance that moisture will reach the rafters, especially in high-humidity conditions.

Therefore, pressure-treated wood will offer you peace of mind knowing that your roof rafters can withstand this natural element. Furthermore, while the International Building Code does not specifically mention roof rafters, it has a provision that requires all structural and siding timber used within the structure’s topmost 6 inches to be pressure-treated.

Conclusion

As the adage goes, better safe than sorry. It would be best to use pressure-treated wood for roof rafters than use untreated timber and risk replacing the entire roofing after a few years. This decision will cost you more, but it is worth every penny.