To achieve that pristine cut and avoid blade burning when ripping hardwoods, selecting the right blade is paramount. Identifying the need for a ripping blade marks only half of the challenge; navigating through numerous brands and various ripping blades within each brand presents a daunting task. Amidst these choices, a plethora of features demands attention. However, fear not, for I am here to streamline the process for you in the quest to finding the best table saw blades for ripping hardwood. Let’s start by examining the four crucial factors that I always inspect in my ripping blades, which serve as my benchmarks for giving them a pass.

Recommended reading: Best Combination Blades

4 Factors you should not overlook

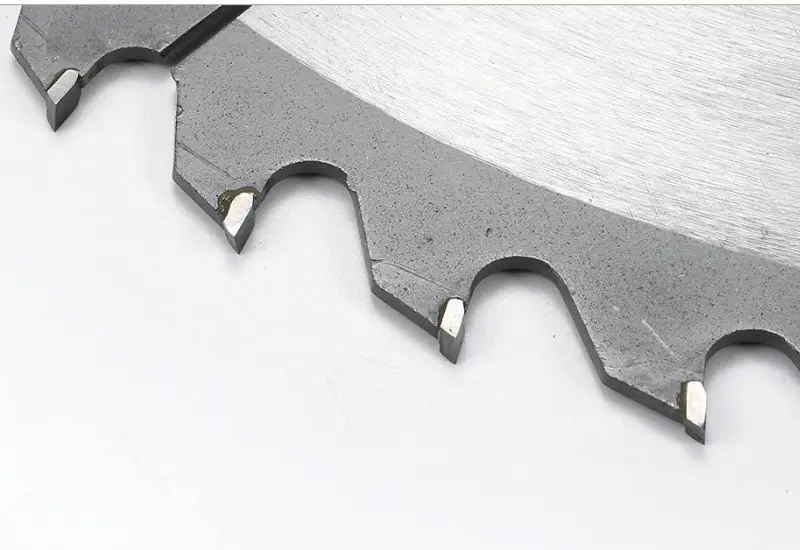

- Tooth Design and Count: The tooth design and count on the blade have a profound impact on the quality of your rip cut. For optimal ripping performance, a blade with a low tooth count (around 24 to 30 teeth) and a flat-top tooth design prove ideal. This configuration ensures swift cutting with efficient chip removal, minimizing the risk of wood burning.

- Tooth Hook Angle: A critical factor in ripping hardwoods is the tooth hook angle, which refers to the teeth’s tilt concerning the blade’s centerline. For top-notch results, a positive hook angle (typically between 10 to 20 degrees) is preferred. This angle empowers the blade to bite aggressively into the wood, boosting cutting speed while preventing kickback.

- Kerf Width: The kerf width, denoting the thickness of the slot cut by the blade in the wood, plays a pivotal role in the cutting process. Opting for a thinner kerf width offers advantages like reduced power consumption and minimized waste, making your cutting endeavors more efficient. Nevertheless, always ensure the blade is compatible with your saw’s arbor size and can handle the thinner kerf design. More on Kerf later on.

- Blade Material and Quality: The material and overall quality of the blade are of utmost importance in determining its performance and durability. When ripping hardwoods, carbide-tipped blades emerge as a popular choice, as they maintain sharpness for prolonged periods and withstand the abrasive nature of hardwoods. Look for blades from reputable brands renowned for their quality and longevity.

Of course, there are other factors to consider, but these four hold the greatest significance for me. Rest assured, I have more considerations that we will explore later. For now, let me present you with five blades that I believe will never disappoint when ripping hardwoods. Each of these blades meets the four essential factors mentioned earlier, and in some cases, they may even come with additional features or benefits.

Read Next

• https://improvewood.com/best-ripping-blade-for-table-saw/

• https://improvewood.com/table-saws-an-overview/

• https://improvewood.com/best-table-saw-for-small-shop/

• https://improvewood.com/best-combination-table-saw-blade/

• https://improvewood.com/blades-for-ripping-hardwood/

• https://improvewood.com/best-woods-for-turning/

Best table saw blades for ripping hardwood

Undoubtedly, the best table saw blade for ripping hardwood stock is The Forrest Woodworker II 10″ 20T Atb+R Blade. Not only does it flawlessly meet our checklist of essential factors, but it is also my favorite for its exceptional durability. When it comes to hardwoods, we all know they can be quite demanding, and the last thing any woodworker wants is to constantly replace blades every few months. If you seek a blade that stands the test of time with remarkable endurance, this is undoubtedly the one to go for.

Renowned among woodworkers, the Forrest Woodworker II Raker Blade is a testament to unparalleled craftsmanship and ingenuity. With durability unmatched by any other brand Forrest Blades has Meticulously crafted this raker blade with precision engineering, guaranteeing flawless Ripping of soft and hardwoods and exceptional results with every use.

Why pick this blade

- Durability: Investing in a tool that lasts is crucial, and the Forrest Woodworker II delivers on this front. While the initial cost may be higher, remember the old adage “You get what you pay for,” and this blade exemplifies that perfectly. With DOUBLE HARD and 40% stronger C-4 carbide, this blade offers exceptional durability, providing up to 300% longer life between sharpenings.

- Precision Rip Cuts: The flat-top tooth design with a low tooth count (20T) ensures swift and precise rip cuts, minimizing the risk of wood burning.

- Efficient Chip Removal: The optimized tooth design ensures efficient chip removal during cutting, leading to smoother and cleaner results.

- Enduring Sharpness: The C-4 carbide tips maintain their sharpness for prolonged periods, allowing you to achieve consistent cutting performance.

- Unsurpassed Smooth Cuts: The Forrest Woodworker II 10″ 20T ATB+R Blade is designed to deliver unsurpassed smooth cuts right from your saw machine. Its precision-engineered design ensures flawless results, eliminating the need for additional finishing steps.

- Perfect for Resurfacing: No need to cut 1/16˝ oversize to accommodate for resurfacing. The blade’s exceptional engineering ensures accurate cuts, reducing material waste and maximizing efficiency.

- Effortless Feed: The 20° face hook of this blade guarantees effortless feed, making ripping hardwoods smoother and more enjoyable.

- Engineered Clearances for Side Scoring Elimination: The specially engineered clearances on the carbide teeth eliminate side scoring, resulting in clean and seamless finishes. Experience exceptional cutting performance without the need for additional planing, jointing, or sanding.

Now, let’s apply our four-factor spectrum to see how well this blade fits the hardwood ripping position:

Four-Factor Spectrum:

- Tooth Design and Count: With its low tooth count and flat-top tooth design, the Forrest Woodworker II is perfectly tailored for ripping hardwoods with precision and ease.

- Tooth Hook Angle: The 20° face hook angle empowers the blade to bite aggressively into the hardwood, ensuring a smooth and efficient cutting process.

- Kerf Width: The blade’s thin kerf width minimizes waste and power consumption while making it compatible with a variety of table saws.

- Blade Material and Quality: The Forrest Woodworker II’s C-4 carbide tips and DOUBLE HARD feature exemplify its top-notch material and overall quality, ensuring exceptional performance and longevity.

Best ripping blade for hardwoods with glue line finish

Precision ripping can be a game-changer, saving you valuable time and avoiding unnecessary hassle. When working with an imprecise blade, you might find yourself having to run your boards through a jointer after ripping just to achieve the desired smoothness. However, the Freud LM74R010: 10″ Industrial Glue Line Ripping Blade stands out in a league of its own, offering an exceptional level of precision that eliminates the need for additional jointing. This remarkable blade delivers an impressively smooth and precise cut, leaving you with edges so clean that jointing becomes unnecessary.

While its precision is the primary reason why I admire this blade, it also excels in handling heavy ripping tasks, especially when dealing with hardwoods.

With the Freud LM74R010, you can confidently tackle any rip-cutting task, knowing that the final result will meet the highest standards of quality and precision. Its ability to produce glue-ready edges directly off the saw is a testament to its exceptional craftsmanship. Say goodbye to time-consuming jointing and embrace the convenience and perfection that this blade brings to your workshop.

Why pick this blade:

- Precision Ripping: The Freud LM74R010: 10″ Industrial Glue Line Ripping Blade offers an unparalleled level of precision, making it a game-changer in your woodworking projects. With this blade, you can achieve smooth and clean edges directly off the saw, eliminating the need for time-consuming jointing after ripping.

- Well-Balanced, Anti-Vibration Design: With a precision-balanced and pre-tensioned construction, the Freud LM74R010 ensures truer cuts even under heavy loads. Its laser-cut, anti-vibration slots significantly reduce chatter, resulting in cleaner finishes, extended blade life, and reduced noise during operation.

- High-Density Carbide for Maximum Cutting Performance: The glue line rip saw blade’s 30 teeth are crafted with Freud’s application-specific TiCo high-density carbide “ripping blend.” This unique blend of improved density, hardness, corrosion resistance, heat resistance, and impact resistance perfectly suits the demands of ripping large quantities of soft or hard wood. The blade’s sharpened starting teeth and enhanced edge retention enable longer intervals between sharpening, saving you both time and money.

- Perma-SHIELD Coating Reduces Friction and Heat Buildup: Crafted to withstand rigorous use under less-than-ideal conditions, this blade features Freud’s red Perma-SHIELD coating. This non-stick coating effectively reduces friction and nearly eliminates heat buildup that excess friction can cause. With complete thermal insulation, the coating protects your tools and work surface, while also resisting binding during large-volume cutting applications to prevent blade warp

Four-Factor Spectrum:

- Tooth Design and Count: The Freud LM74R010 excels in tooth design and count, featuring 30 premium TiCo HI-Density carbide teeth. This specialized ripping blend ensures maximum performance, providing clean and precise cuts through hardwoods and other materials.

- Tooth Hook Angle: With a tooth hook angle of 12°, this blade is optimized for aggressive ripping, making it an ideal choice for heavy-duty tasks. The combination of the tooth design and hook angle enables efficient material removal and minimizes the risk of binding during the cut.

- Kerf Width: The Freud LM74R010 boasts a thin kerf width of .118″, resulting in reduced waste and power consumption. This efficient design allows for smoother cuts while preserving the integrity of the hardwood stock.

- Blade Material and Quality: Crafted with a heavy-duty thick plate (.098″), this blade ensures stability and flatness for extended cutting life. The premium TiCo HI-Density carbide and laser-cut anti-vibration slots significantly reduce vibration and sideways movement during cutting. This not only extends the blade’s life but also guarantees a crisp, splinter-free, and flawless finish on your woodworking projects.

Moreover, the blade’s Perma-Shield Non-Stick Coating plays a vital role in enhancing its performance. This coating reduces blade drag, protecting it from corrosion and pitch build-up. The non-stick feature allows for smoother cuts and ensures that the blade remains in excellent condition even after prolonged use.

The budget pick

At times, finding the right balance between features and budget becomes necessary. It’s all about making informed trade-offs, especially when seeking cost-effective options. The truth is, you can still find highly capable blades that deliver satisfactory performance without breaking the bank – all while meeting your specific needs. Remember, it’s not always about the highest-priced option; value can be found in various price ranges.

For this category, my personal favorite ripping blade is the Freud America LM72R010: 10″ Heavy-Duty Rip Blade. I know that there are cheaper ripping blades out there, but this blade stands out as the best option that can handle hardwoods while providing you with decent cuts and long-lasting performance.

The 10-inch Freud LM72R010 Heavy-Duty Rip Saw Blade is crafted for serious woodworkers seeking precision and reliable performance. Its exceptional features make it a top choice for handling tough industrial ripping tasks with ease.

Why pick this blade:

- Professional-Grade Design for Accurate Glue Line Cuts: The Freud LM72R010 Heavy-Duty Rip Saw Blade is specially designed for serious woodworkers, offering fast and precise “glue line” cuts without the need for stabilizers. Its anti-kickback design ensures safety during tough industrial ripping tasks. It excels in handling hard- or softwoods ranging from 3/4 to 2-3/4 inches thick and can be used in gang-rip operations. The blade also handles crosscuts with materials like chipboard, plywood, and laminate, making it a versatile choice for various projects.

- Extra-Large, Flat Teeth for Splinter-Free Finish: Featuring 24 oversized, flat-top teeth with TiCo high-density carbide tips, this blade leaves a smooth, splinter-free finish, eliminating the need for additional sanding and jointing. The large-tooth design allows the blade to be safely sharpened multiple times, extending its lifespan and providing cost savings. Additionally, the large gullets between teeth ensure easy chip removal for efficient cutting.

- Well-Balanced, Anti-Vibration Design: Precision balanced and pretensioned for truer cuts under heavy loads, this blade boasts laser-cut, anti-vibration slots that reduce chatter and deliver a cleaner finish. The design not only prolongs blade life but also minimizes noise during operation. Its high-strength steel construction ensures stability, flatness, and true cuts even after prolonged use.

- High-Density Carbide for Maximum Cutting Performance: The Freud LM72R010 features teeth made from Freud’s TiCo high-density carbide “ripping blend,” offering superior density, hardness, corrosion resistance, heat resistance, and impact resistance. This blend perfectly suits the demands of ripping large quantities of thick, hard wood. With sharper starting teeth and improved edge retention, the blade requires less frequent sharpening, saving time and money in the long run.

The Four-Factor Spectrum:

- Tooth Design and Count: The Freud LM72R010’s 24 oversized, flat-top teeth with a low tooth count (24T) ensure swift and accurate rip cuts through hardwoods, minimizing the risk of burning and delivering exceptional results.

- Tooth Hook Angle: While the exact tooth hook angle is not mentioned in the description, the blade’s anti-kickback design suggests a positive hook angle that enhances cutting speed and prevents kickback during tough ripping tasks.

- Kerf Width: The blade’s kerf width is specified as 0.126 inches, which indicates a relatively thin kerf that reduces waste and power consumption while maintaining compatibility with a variety of table saws.

- Blade Material and Quality: The Freud LM72R010 incorporates Freud’s high-density carbide “ripping blend” tips, ensuring top-notch material and overall quality for exceptional cutting performance and extended blade life.

With its impressive features, durability, and precision, The Freud LM72R010 Heavy-Duty Rip Saw Blade presents itself as a budget-friendly option without compromising on performance. Whether you’re a seasoned woodworker or a DIY enthusiast, this blade is a reliable companion that guarantees outstanding results in your hardwood ripping endeavors. So, embrace the benefits of this budget pick, and let your woodworking projects flourish with precision and efficiency.

Now that we have explored the top 3 blades for ripping hardwoods, let’s delve into additional factors that you should consider before making your purchase.

What kerf size is ideal for hardwoods?

The ideal kerf size for hardwoods is a critical consideration that can significantly impact the efficiency and precision of your cuts. Several factors come into play when determining the optimal kerf size, such as the type of saw being used, wood thickness, and desired cut accuracy. Striking the right balance between accuracy and waste is essential.

Smaller Kerf Size (e.g., 3/32 inch):

- Benefits: Produces less waste, allows for more precise cuts, and requires a sharper blade.

- Considerations: Requires careful sawing to avoid tear-out, may be best suited for less powerful table saws.

Larger Kerf Size (e.g., 1/8 inch):

- Benefits: Easier to saw, less prone to blade binding, suitable for powerful saws.

- Considerations: Produces more waste compared to a smaller kerf size.

Selecting the most appropriate kerf size hinges on the specifics of your woodworking tasks. If you’re working with a less powerful table saw, opting for a thinner kerf blade (e.g., 3/32 inch) could yield less waste and provide greater precision. However, if you’re using a powerful saw, a slightly thicker kerf blade (e.g., 1/8 inch) might be better suited to avoid blade binding.

Below is a summarized table of the different kerf sizes, their respective benefits, and considerations:

| Kerf Size (Inches) | Benefits | Considerations |

|---|---|---|

| 3/32 | Less waste, precise cuts | Requires a sharper blade, tear-out |

| 1/8 | Easier sawing, less blade binding | More waste compared to smaller kerfs |

Durability vs Budget vs Precision

When looking for a suitable ripping blade for hardwoods, sometimes it comes to picking between durability, budget, and precision. While this may be a difficult decision, there are a few things to keep in mind that can help you make the best choice for your needs.

Durability:

If you prioritize long-lasting performance and want a blade that can withstand heavy and continuous use, then opting for a durable ripping blade is crucial. High-quality blades with premium materials, such as carbide-tipped blades, offer exceptional durability, allowing you to work with hardwoods without frequent blade replacements. While these blades may have a higher upfront cost, their extended lifespan saves money in the long run.

Budget:

For woodworkers on a tight budget or those who engage in occasional woodworking projects, a more budget-friendly ripping blade might be the preferred choice. While these blades may not have the same level of durability as high-end options, they still get the job done and provide decent performance at a lower cost. However, keep in mind that they might require more frequent sharpening or replacement, especially when working with dense hardwoods.

Precision:

When precision is your top priority, investing in a high-precision ripping blade is essential. Blades with specialized tooth designs and precise manufacturing ensure smooth, clean cuts with minimal tear-out. If you work on intricate projects or require glue-ready edges without the need for additional finishing, a precision ripping blade is well worth the investment. These blades may fall into the higher price range, but they deliver superior results, making them ideal for professional woodworkers and those who value fine craftsmanship.

Making the Decision

So, how do you decide which factor is most important to you? It really depends on your individual needs and preferences. If you need a durable blade that will last for years, then you may be willing to spend more money. However, if you are on a tight budget and you don’t need the most precise blade, then you may be able to get away with a less expensive blade.

Ultimately, the best way to decide which factor is most important to you is to consider your specific needs and preferences. Once you know what you are looking for, you can start shopping around for a blade that meets your needs.

Summary: best blades for ripping hardwood

In conclusion, whether you prioritize durability, budget, or precision, there is a perfect ripping blade to suit your needs. Each of these blades excels in its respective category, ensuring unparalleled performance and exceptional results in your hardwood ripping endeavors. Now armed with this knowledge, you can confidently unleash the full potential of your table saw and elevate your woodworking projects to new heights of precision and craftsmanship. Happy ripping!