Woodworking is an art that requires a good understanding of the different techniques available for shaping and manipulating wood. One such technique is bending, which allows you to create elegant curves and shapes in your woodworking projects. While there are various methods for bending wood, steam bending is an effective and popular technique that involves using steam and heat to make wood more pliable. In this article, we will focus on the steam bending method and explore its advantages and disadvantages, as well as the steps involved in creating a simple pipe steamer to aid in your projects.

Related Reading

How to unwarp wood

Best woods for bending

When selecting wood for bending, moisture content is a key consideration. Green or freshly cut wood is highly recommended for bending since it is easier to bend without cracking or breaking due to its higher moisture content. However, bending green wood requires more drying time on the form and has a greater risk of cracking during that time. In contrast, air-dried wood is more difficult to bend without damage, but it may be better for achieving precision.

Types of Wood and Their Bendability

When selecting wood for bending, it’s essential to consider the inherent properties of different types of wood that affect its bendability. Among the best woods for steam-bending are red oak, white oak, and white ash. Red oak is an excellent wood to start with, due to its straight grain and minimal defects, while white oak is generally fabulous for steam-bending. White ash is a superb alternative to oak if the parts are to be stained.

Sweet gum is incredibly flexible but prone to warping, and red maple is generally more elastic than cherry but slightly weaker. While cherry is very good for steam-bending, it requires a compression strap. Walnut is also a viable option, but its wide range of elasticity, weight, and strength can make it challenging to bend.

Hickory is another species that varies greatly in its bendability, with some sub-species being great for bending and others nearly impossible. Therefore, it’s crucial to inspect the wood carefully and select the right species and quality to ensure successful wood bending.

Observing grain direction

Wood is not uniform, and each plank has its own weak and strong spots, depending on the grain’s direction. The grain’s straightest part, which runs parallel to the board’s edge, is the strongest, while the weakest area has the most “run-out” caused by crooked or branched parts of the tree.

As a woodworker, these subtle differences may give wood its character, but for successful steam bending, they’re critical information. During the bending process, the wood will offer the least resistance where there’s the most run-out. To prevent the weakest parts from developing kinks that can lead to cracks, it’s important to support and clamp the wood. By planning ahead and using the straightest grain over the bend’s tightest part, you can achieve the desired outcome.

Read Next

- How to Soften Wood for Carving: 10 Different Ways

- Straighten Wood with Water

- Understanding Wood: Properties and Characteristics

- Best Method for Joining Wood

- 30 Woods That Can Be Used for Adirondack Chairs

Recommended wood bending ratio

For bends tighter than a 1:10 thickness-to-radius ratio or questionable wood quality, a steel compression strap can provide extra support. Typically, a ratio of 1:5 thickness to radius is the limit recommended. But, with straight-grained ash, oak, elm, or yew, even tighter results of 1:2 thickness to radius or tighter are possible with the right setup.

Using a wood-bending steamer

Steam-bending wood is a beautiful combination of art and science that requires a deft touch. While breaking wood during the process may seem like a setback, it provides an opportunity to learn and perfect the technique. The continuous learning process and the chance to create stunning pieces keep woodworkers hooked on this fascinating craft.

The steam plays a crucial role in the process by softening the wood and making it easier to bend. It breaks down the lignin present in the wood cells, making it more pliable to manipulation into a new shape. This method is particularly effective for creating curved or twisted shapes that would be difficult to achieve through other woodworking techniques.

The best steamer for wood bending

The Earlex Steam Generator-Wood Bender is a top-of-the-line steam generator that comes equipped with a hose for easy insertion into your steam box. With its user-friendly manual, this steamer is incredibly easy to use. All you need to do, besides building your steam box, is drill a hole for the fitting that connects the steam hose to the box. The manual also includes a comprehensive set of instructions for building your own steam box out of plywood.

Mastering the science of steam-bending wood requires a keen understanding of the material’s grain, particularly for makers who lack access to industrial bending tools.

How to Make a Pipe Steamer for Bending Wood

Bending wood can be a challenging but rewarding process that opens up new possibilities for woodworking projects. One way to make the job easier is by using a pipe steamer, which can be easily constructed using a few simple materials. Here’s how to make one:

Materials Needed:

- Plastic pipe, at least 8 feet (2.5 meters) long and 3 15/16 inches (100mm) wide (HDPE or polypropylene are better choices than PVC)

- Aluminum tape

- Wood, foam, or plastic to seal the ends (optional)

- Insulation for the pipe, such as a boiler insulation jacket (optional)

- Wallpaper stripper/steam generator

Instructions:

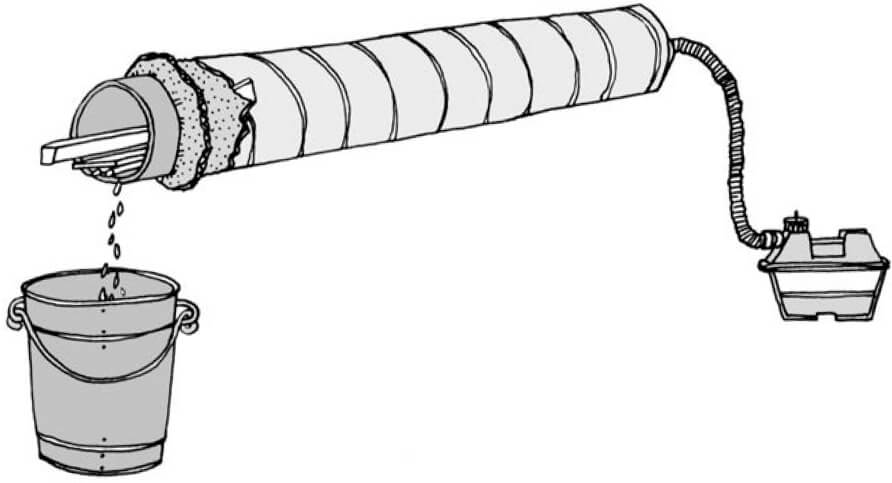

- Choose a plastic pipe that can withstand the heat without softening. If necessary, insulate the pipe, especially if your workshop is cold or draughty. Place the pipe on a horizontal surface, sloping slightly downwards to allow excess water to drain into a bucket.

- Position the steam-pipe from the wallpaper stripper at one end of the plastic pipe. You can secure it in place by inserting it through a plug of wood, foam, or plastic, or by carefully sealing it with silver aluminum tape.

- Insert the wood you want to bend into the other end of the plastic pipe, making sure it is snug but can still move freely. Seal the other end with another plug or aluminum tape, leaving a few small holes or gaps for the steam to escape and the water to drain out.

Your pipe steamer is now ready to use! With this simple tool, you can easily heat the wood to make it more pliable and easier to bend without cracking or breaking. Happy woodworking!

Steam Bending Wood: A Summary

In conclusion, steam bending is an effective and popular technique for creating curved or twisted shapes in woodworking projects. However, selecting the right wood, observing the grain direction, and using the correct ratio of thickness to radius are all crucial factors in achieving success. The Earlex Steam Generator-Wood Bender is a top-of-the-line steamer that can make the job easier. A pipe steamer can also be constructed using a few simple materials, further simplifying the process. With practice and attention to detail, woodworkers can master the science of steam-bending wood and create stunning pieces that showcase the beauty and versatility of this fascinating craft.