The effectiveness of lacquer is influenced by the solvents utilized for its solution. Different solvents evaporate at varying rates, allowing control over the curing speed. In this article, we delve into lacquer application techniques and the fundamentals of thinning, providing insights into managing the cure time through solvent selection.

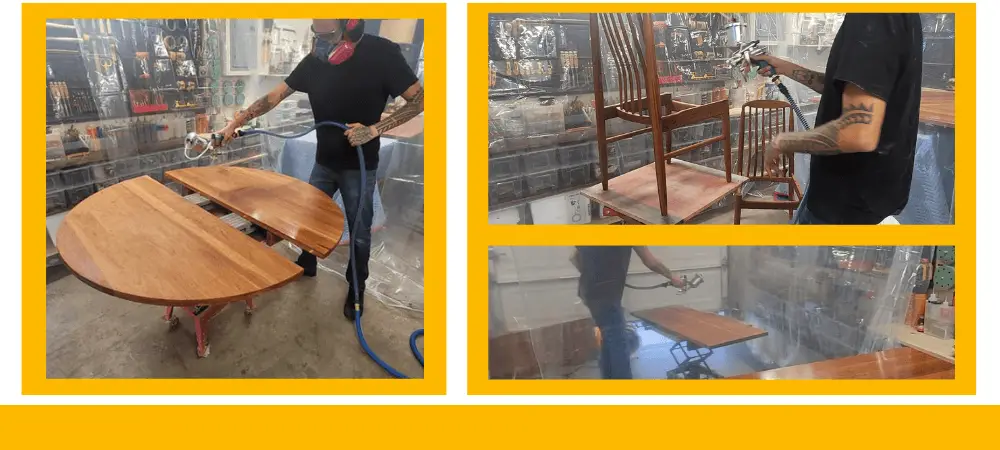

Optimizing Your Spray Booth Setup for Effective Work

Creating a well-organized and spacious area is crucial for smooth operations. Adequate lighting is essential to ensure visibility and accuracy. Arrange your workspace strategically, so as you can see whats happening through reflected light. You should also ensure enough space all around the piece for easy accesibility.

How to spray lacquer

- Follow the manufacturer’s instructions to thin the lacquer, or thin it until drops break off the stirring stick.

- Apply the thinned lacquer as a sealer coat, ensuring even coverage.

- Allow the coat to cure, then use 280-grit sandpaper to gently sand the surface, smoothing out any raised wood grain. Be careful not to over sand.

- Remove the sanded dust by vacuuming or using a tack cloth or brush.

- Apply the next coat of lacquer and allow it to cure.

- If there are any dust nibs or surface imperfections, sand the new coat with stearated sandpaper. Otherwise, sanding between coats is not necessary.

- Repeat the process, applying subsequent coats until you are satisfied. Typically, 3 to 4 coats are sufficient if you are not aiming to fill the pores of the wood.

- The final coat can be left as is or it can be finished off with sandpaper, steel wool, or rubbing compounds.

Controlling Lacquer Curing Time with Lacquer Thinners

The choice of lacquer thinners plays a crucial role in managing the curing speed of lacquer. This information may seem overwhelming, but it offers important benefits:

- Compensate for abnormal weather conditions, ensuring optimal spraying conditions (around 70°F with humidity in the 40s).

- Improve flow-out, minimizing the occurrence of orange peel texture on the surface.

- Maintain a wet area when working on large projects, allowing for consistent application.

- Slow down the curing process, enabling brush application of lacquer.

Understanding the role of lacquer thinners empowers you to achieve desired results and adapt to different lacquering scenarios

Read Next

- How to Clean Polyurethane

- Can You Spray Polyurethane with an Airless Sprayer?

- Best HVLP Spray Gun for Woodworking

- Polyurethane on Painted Cabinets

- Cleaning and Storing Polyurethane Brushes

- Best Polyurethane for Pine Floor

Comparison of Lacquer Thinners for Curing Control

| Thinners | Evaporation Rate | Curing Speed | Availability |

|---|---|---|---|

| Standard Lacquer | Normal | Standard | Widely available in lacquer stores |

| Retarder | Slower | Slower | Available in lacquer stores |

| Fast Lacquer | Faster | Faster | Mostly found in auto-body paint stores |

Using standard lacquer thinner as a starting point is recommended for normal curing speed. If you need to slow down the curing process, adding lacquer retarder is an option. For faster curing, incorporating fast lacquer thinner can be beneficial. While standard lacquer thinner and lacquer retarder are commonly found in lacquer stores, fast lacquer thinner may require a visit to specialized auto-body paint stores. Understanding the differences among these thinners allows for better control over the lacquer curing time

How To spray Lacquer Conclusion

In conclusion, achieving a flawless lacquer finish requires attention to detail and proper techniques. By optimizing your spray booth setup, ensuring sufficient space and lighting, you can create an ideal working environment. Following a step-by-step guide, including thinning the lacquer, applying coats, and sanding in between, will help you achieve a smooth surface.

Additionally, understanding the role of lacquer thinners and their effects on curing speed allows for greater control over the process. Whether you’re compensating for weather conditions or seeking to improve flow-out, selecting the appropriate lacquer thinner is essential. With this knowledge, you can confidently spray lacquer and achieve the desired results in your woodworking projects.

No, you cannot apply polyurethane over lacquer because the two will not bond. Over time, the polyurethane coat will peel and flake. Instead of polyurethane, use alkyd varnish to protect your lacquer finish from water damage and scratches.