The Laguna 1216 Lathe is a popular choice among woodworkers for its impressive features and ease of use. However, like any other machinery, the Laguna 1216 Lathe has its problems from motor issues to malfunctioning controls and other issues. These problems can be frustrating and lead to delays and decreased productivity in the workshop.

However, nothing new has happened, and a solution is still missing. In this blog post, we’ll explore some common problems that many woodturners encounter with their Laguna 1216 lathe and provide tips and solutions for fixing and overcoming them. Next time don’t let these problems slow you down – read on to find out how to keep your Laguna 1216 lathe running smoothly.

The Laguna 1216 Lathe Common Problems and Solutions

Control board issues

One of the common problems with the Laguna 1216 lathe is control board issues. The control board is an integral component of the lathe’s electronic system, responsible for controlling the various operations of the lathe. In essence, the control board serves as the central hub for operating machinery.

Symptoms

Some common symptoms of control board issues include unresponsiveness of the control panel, errors in the display, or sudden shutdown of the lathe.

Solving the Problem

For you to solve the control board issues, the first step is to ensure that you connect the lathe to the power supply correctly.

Check if there are any loose connections. Sometimes, a loose or faulty power cable could cause the lathe to malfunction. Look for any signs of damage in the cord or if there are loose connections in the terminals. If there’s any damage to the cord, consider replacing it or fixing accordingly. For loose connections in the terminal, tighten it. If this doesn’t solve the problem, inspecting the control board itself may be necessary. Additionally, ensure you regularly clean the dust from the circuit board and the switches.

If it continually fails to function correctly, the control board may need to be replaced or repaired by a professional technician.

To prevent control board issues from occurring in the future, make sure to use the lathe according to the manufacturer’s instructions. Avoid overloading the lathe or subjecting it to excessive wear and tear. Always unplug any electronically controlled device when not in use. I’m convinced many control board failures to result from line disturbances like lightning. Also, an unstable electrical supply like you have in some rural areas can wreak havoc on control boards.

Always maintain regular maintenance, including cleaning and lubricating the control board and other components, which can also help prevent control board issues.

While control board issues can be frustrating, they are generally easily fixable. With some simple troubleshooting and proper maintenance, your Laguna 1216 lathe can continue functioning properly for many years.

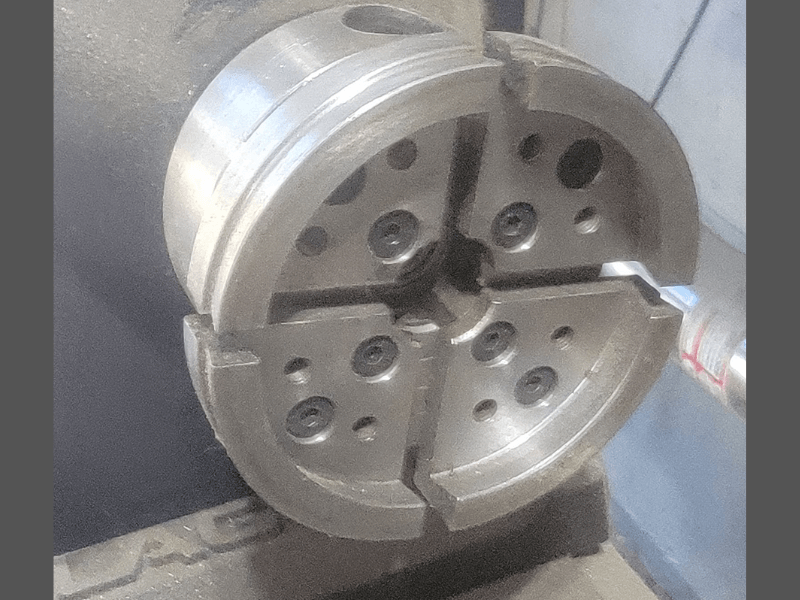

Chuck keeps coming loose.

There are usually two places where a chuck uses threads that can become loose: One is where the chuck is screwed onto the spindle that typically stays tight unless you run in reverse, and the second thing that loosens is the chuck jaws themselves (wood moves around a lot).

Solving the Problem

To fix the issue of the chuck coming loose from the spindle, check the set screw and ensure it is tight. Additionally, make sure that the chuck is securely tightened onto the spindle.

If the issue is with the chuck jaws, you can periodically tighten them to ensure a secure grip on the wood. You can use a chuck key or a wrench to turn the jaws clockwise until they are tight.

It is essential to maintain it properly to avoid any potential issues with the chuck becoming loose on your Laguna 1216 lathe. This involves keeping the chuck and spindle threads clean regularly. Additionally, ensuring that the chuck is appropriately lubricated is crucial, as is regularly inspecting and tightening the chuck jaws. By implementing these maintenance practices, you can help prevent any future problems with your lathe.

In summary, the issue of the chuck coming loose on the Laguna 1216 lathe can be solved by tightening the set screw or the chuck jaws. Proper maintenance and inspection of the lathe can also prevent future issues.

Difficulty in changing speeds

Another common problem faced by Laguna 1216 lathe owners is difficulty changing speeds. Changing speeds can be time-consuming and complicated, especially for new users who need to become more familiar with the procedure.

Symptoms

We have different cases where some users have raised concerns on their first interaction with their lathe. Some reported that the speed dials on their machine were not easy to turn and that the spindle did not respond to changes in speed settings. Others complained about the belt slipping once they changed the speed of the machine, failing to lock into a particular speed.

Solving the problem

If you are having trouble changing speeds on your Laguna 1216 lathe, there are a few things you can do:

First, make sure that you are following the instructions provided in the user manual. The manual will have detailed information on how to change the speed and troubleshooting tips in case you encounter any issues.

If the belt kept slipping every time you changed the speed and the lathe failed to lock into one speed, the problem is definitely because of the worn-out belt. To diagnose and solve this, make sure you check the belt’s condition and replace it if it shows signs of wear and tear. Additionally, ensure the machine is lubricated correctly, as a lack of lubrication can cause the belt to slip.

If you have tried these steps and are still experiencing difficulty, it may be time to contact the manufacturer or a professional technician. They can diagnose the problem and recommend the best course of action.

Loss of torque periodically

One of the frustrating problems that many woodturners often experience with the Laguna 1216 lathe is a periodic loss of torque. This issue is very hectic, especially if you’re working with deadlines or working on very delicate projects. The issue is usually due to several factors, such as the wear and tear of the belt, worn bearings, and even insufficient lubrication.

Symptoms

Some common symptoms that result from changes in torque are the change of temperature in the machine. It becomes very hot. Another alarming concern is when you change the speed levels and the lathe fails to respond. You find that the motor is making an unusual sound.

Solving the Problem

If you are experiencing a loss of torque periodically, the first step is to inspect the belt to see if it has any visible wear and tear. If so, it may need to be replaced. Similarly, inspect the bearings and lubrication levels to ensure they are up to par.

Another cause of this problem could be related to the motor control board. You may need a professional technician to diagnose and repair the issue.

In addition to the above, make sure to check your power supply. A sufficient power supply can also lead to a loss of torque, mainly when working with large or heavy pieces of wood. To prevent a loss of torque, always ensure that the lathe is running at the correct speed for the size of your workpiece, and take breaks regularly to avoid overheating.

Regular lathe maintenance is also crucial, as it helps identify potential problems before they become more significant.

Overall, if you experience a loss of torque periodically, there are several potential causes. By diagnosing and addressing the issue adequately, you can ensure that your Laguna 1216 lathe performs at its best, allowing you to create beautiful pieces of woodworking easily.

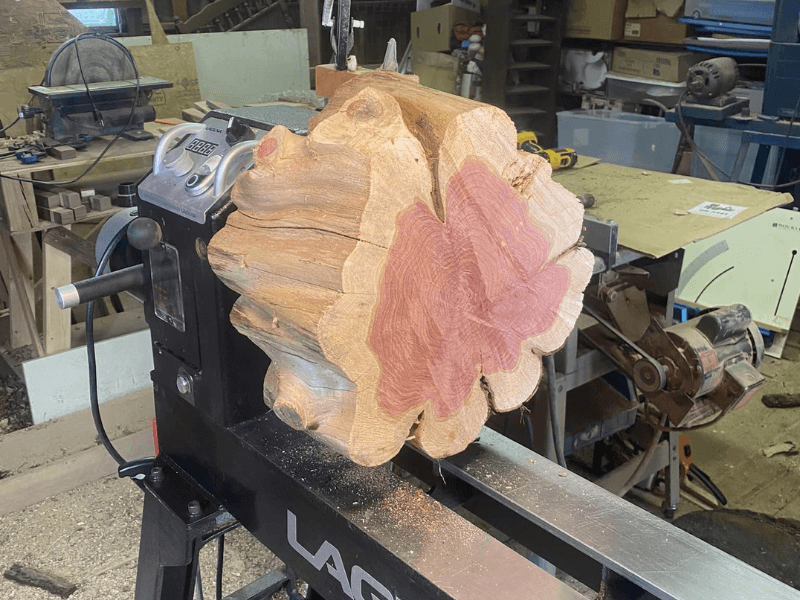

Difficulty maintaining speed when turning larger bowl blanks.

One common problem many woodturners face using the Laguna 1216 lathe is the difficulty of maintaining speed when turning larger bowl blanks, leading to inconsistent cuts and ultimately resulting in an unsatisfactory finished product.

Symptoms

The issue with maintaining speed often arises when working with larger bowl blanks because of the extra weight and force required to turn them. The lathe motor can need help to maintain a consistent speed under these conditions, leading to a lack of torque and fluctuating speeds.

Solving the problem

To tackle this problem, you can implement a few solutions. One option is to use a lower speed setting on the lathe. This may help maintain the speed by putting less strain on the motor.

Another option is to reduce the material you remove at once. You can do this by using more minor cuts and taking your time, allowing the lathe to maintain a steady speed.

Another solution to this problem is to upgrade to a more powerful motor. A more powerful motor will handle larger bowl blanks and maintain a consistent speed more effectively. However, this can be expensive and may only be viable for some.

To prevent future problems when working with larger bowl blanks, it’s essential to take care of your lathe and perform regular maintenance. Keeping the lathe clean and lubricated can help prolong its lifespan and prevent any issues that may arise. It’s also crucial to follow the manufacturer’s instructions for usage and maintenance.

In summary, difficulty maintaining speed when turning larger bowl blanks is a common problem with the Laguna 1216 lathe. However, solutions are available, such as using lower speed settings, reducing the material removed at once, and upgrading to a more powerful motor. Additionally, taking care of your lathe through regular maintenance can help prevent issues and prolong its lifespan.

Bad spindle Lock

A frequent problem with the Laguna 1216 lathe is a faulty spindle lock. This feature is critical because it secures the spindle in position, allowing for easy chuck installation or removal. If the spindle lock fails, it can cause inconvenience and increase accident risk.

Symptoms

Certain users have reported spindle lock issues. Some have expressed that their spindle lock fails to engage altogether, while others have observed that it doesn’t remain locked for an extended period.

These occurrences can be attributed to several factors, such as a spindle lock that has worn out, a locking mechanism that is not aligned correctly, or a broken spring.

Solving the problem

If you’re encountering any of these difficulties with the spindle lock, it would be advisable to examine the locking mechanism. It is crucial to ensure that the mechanism is free of debris and clean. If this does not resolve the issue, it may be worth adjusting the locking mechanism to determine if it resolves the problem.

If the issue continues, you might have to change the spindle lock or seek professional assistance to repair your lathe. It is essential to remember that spindle locks can pose safety hazards. Therefore, it is crucial to address them promptly. Avoid using your lathe if the spindle lock fails. It’s better to take precautions and stay safe than regret it later.

Vibration Issues

One of the most annoying problems woodturners face with the Laguna 1216 lathe is vibration. These issues can ruin the quality of your turns and make you feel tired and uncomfortable. It’s frustrating when you’re trying to create something beautiful, and these problems get in the way. So, if you’re using this lathe, be aware of these issues and try to minimize them. It will make your woodworking experience more enjoyable!

Symptoms

If you’re experiencing vibration on your lathe, the first step is to check your tool and the wood blank you’re working on. Ensure your tool is sharp and positioned correctly and the wood blank is secured tightly. If these factors are not the problem, it’s time to look at the lathe.

Solving the problem

One potential cause of vibration is an unbalanced spindle. To solve this problem, ensure you align your spindle appropriately and balance it well. An imbalance can lead to unwanted movement.

Another potential cause is worn or damaged bearings. To solve this problem, you should inspect your bearings for signs of wear or damage and replace them as necessary.

It’s also worth noting that an improper speed setting can cause vibration. Ensure you’re using the correct speed for the wood diameter you’re turning. If you need help determining what speed to use, consult the manufacturer’s guidelines or consult with an experienced woodturner.

If all else fails, it may be time to contact Laguna for assistance. Their customer support team can help you troubleshoot the issue and find a solution that works for you.

Vibration issues can be frustrating to deal with, but they are usually fixable with some careful diagnosis and troubleshooting. By following the steps outlined above and being patient, you can get your Laguna 1216 lathe back in good working order and create high-quality turnings again.

Conclusions

The Laguna 1216 Lathe is a powerful and reliable tool favoured by woodworking enthusiasts. Nonetheless, as with any machinery, it is susceptible to issues and breakdowns. In this blog article, we have addressed some of the most frequent problems users might experience while using the Laguna 1216 Lathe. We have also provided helpful suggestions and techniques for identifying and fixing these problems.

When encountering complex issues or challenges that cannot be resolved through basic troubleshooting, it is strongly recommended to seek assistance from a specialist or the customer service department of the manufacturer.