What sets you on the road to becoming a skilled woodworker is joining two or more pieces of wood to create something useful, durable, and strong. While wood selection, project design, preparation, sanding, and finishing are important, wood joinery is the heart of woodworking. By the end of this article, you will know the major types of joinery and hopefully, you can decide the best method for joining wood for your project.

Methods of Joining Wood

There are hundreds and dozens of complex ways of joining one board to another. Thus, it can be hard to determine the method of joinery that is good for your woodworking project.

As many and as complex, wood joints are just a variety of a few simple themes. There are three main types of joints, which are;

- Worked joints

- Fastening joints

- Glue joints

Worked/Fitted Joints

Worked/fitted joints are practical and decorative. They interlock to provide strength and stability. Boards are precisely cut to fit one another, they can be as simple as butt joints and as complex as scarf joints. Hand-building worked joints can be challenging and time-consuming, but are beautiful and rewarding when executed. Examples of fitted/worked joints are;

- The mortise-and-tenon

- Dovetail joints

- Miter joints

- Dowelled joints

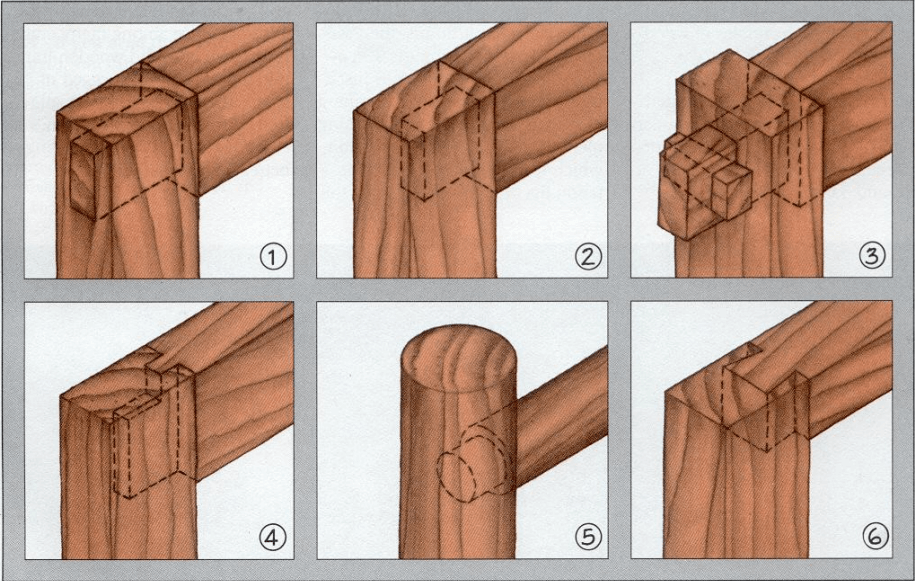

The Mortise-and-Tenon.

Similar to dovetail joints, mortise-and-tenon joints are directly carved and linked into the adjoining wood. The tenon part works as a ‘male’ end or peg and the mortise as the ‘female’ end or slot, into which the tenon is inserted. This joint is designed for wood grains that shrink and expand in different directions. Except for direct withdrawal which is also how a joint comes apart.

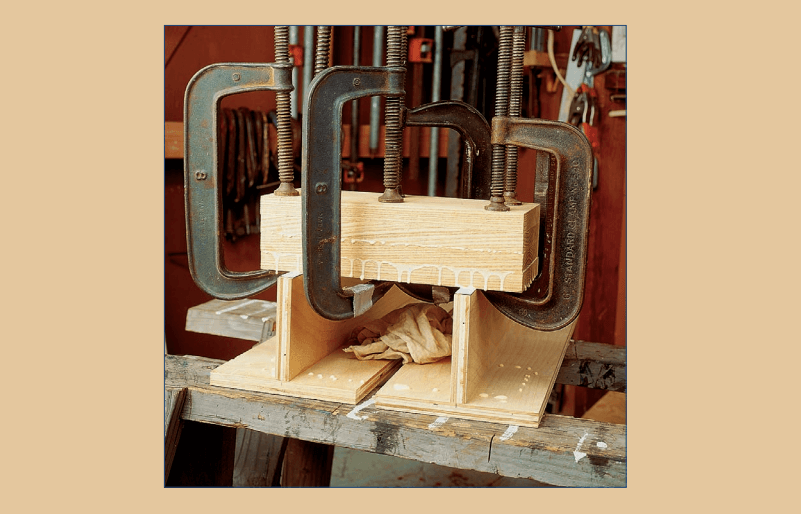

This joint protects the wood from compression, shearing, and racking. Racking, however, when frequent can weaken the dry glue, this can be fixed by re-gluing the joints. Poor drilling or unsharpened tools can weaken the surface of the joint.

Mortis-and-tenon joints are associated with round, square, and rectangular frame constructions; such as window frames, chairs, and box joinery (i.e. drawers and chests).

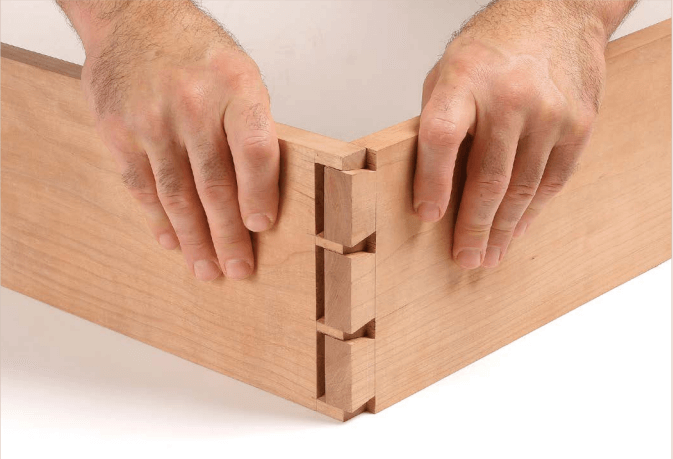

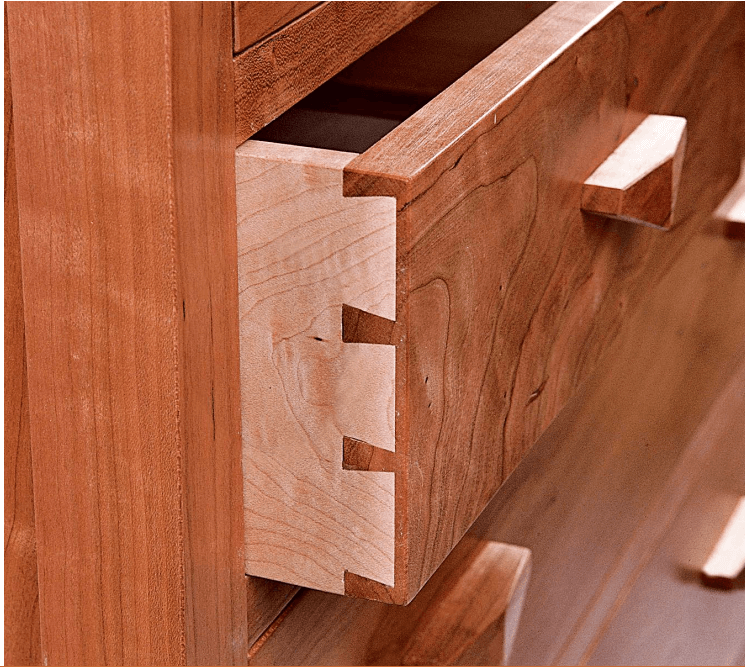

Dovetail Joints

Just like mortise-and-tenon, dovetail joints are directly carved and linked into adjoining wood pieces. In woodworking tradition, the dovetail joint is a symbol of craftsmanship. It’s strong and decorative and it is made up of dovetailed wedges. Dovetails are trapezoidal shapes that interlock with other boards.

The trapezoidal or dovetail shape is called the tail. The other small part in between the wedges is called a pin. While the pieces of wood left on top and under after cutting through dovetail wedges and pins are called half pins.

The interlocking half-pin, pin, and tail joints require only glue to strengthen. No additional hardware is required when using this type of wood joint. For better results, half-pins and pins are required to have an 11 or 12-degree angle.

Read Next

- Strongest Wood Joints for Lasting Projects

- How to Glue Wood Like a Pro

- Tips for Joining Wood Without Gaps

- Woodworking Techniques for Perfect Joints

- Choosing the Right Adhesive for Your Project

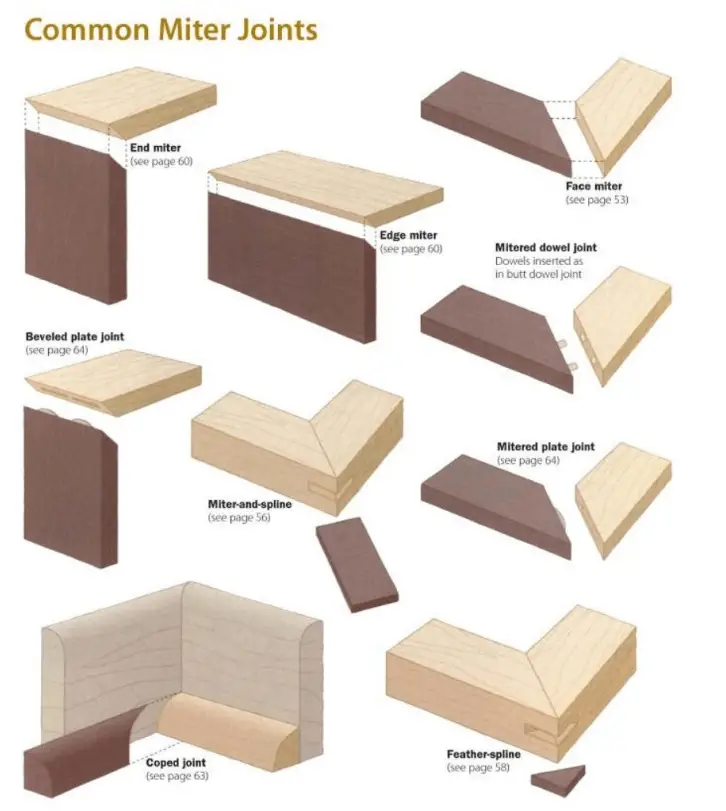

Miter Joints

This type of joint is common among woodworkers because of the miter saw which cuts angles that form miter joints. The miter joint can be defined as a union between two pieces of wood each cut at an angle of 45 degrees. They are then joined together to form a 90-degree angle piece of wood.

The 90-degree angle presents a technical error since dimensional changes occur on both wood grains causing the joint to open. This error can be resolved by gluing and nailing. Deeply and perpendicularly nailing the outside face of either piece of wood would strongly secure them together. Woodworkers also combine miter joints with glues and dowels.

Since the miter joints rely on hardware and adhesives, it’s advisable to cautiously apply them. If the structure loses its strength so does the whole piece. Despite that, it’s the perfect type of joint for framework projects and other angled wood cuts e.g. door corners and picture frames.

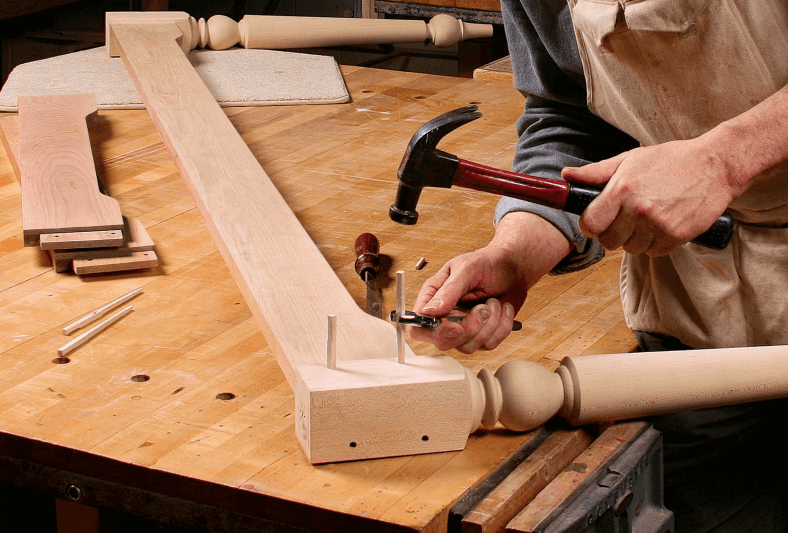

Dowelled Joints

Dowels are wooden cylindrical rods used to fasten and strengthen joints. They can be categorized as; tenons, pins, and gluing accessories. They provide physical constraint to a joint without glue, although glue can still be applied. Dowels are used on pinned slip joints, wooden hinges, or guided in table leaf and flooring pins.

Though similar to mortise-and-tenon joints, dowels are separate pieces of wood. For dowels to fall into place well they need to be long enough to ensure proper alignment. Holes where dowels are to be placed need to be deeper than the dowels for them to fit in accurately.

Gluing and elongating them well enough may seem failproof, but it’s not. Dowels are affected by shrinkage and expansion that cause glue joints to fail. Correcting the gluing procedure will fix the problem.

Fastening Joints

Fastening secures one board to another using wood or metal fasteners such as pegs, nails, and screws. Since most fasteners are metal they have the ability to distribute or transfer tension from one fastener to the other without fail. This however depends on the structural condition of the wood. Examples of fastened joints include; nails and woodscrews.

· Nails

A nail can be defined as a 3 to 4-inch cylindrical piece of metal with a diamond-like sharp end and a flat head. Though very effective, the holding power of nails diminishes over time. Especially when the wood is exposed to extreme moisture, which causes a dimensional change on the wood. This can be solved by modifying the surface of the nail shanks. There are three types of nails; common nails with smooth bright finishes, spiral grooved nails, and annularly grove nails.

Withdrawal resistance can be improved by placing annular grooves on the nail shanks. Annularly threaded nails are harder to drive but they provide a strong resistant surface for bent-over fiber. Spiral threaded nails have better holding power that reduces over a long time this is because they cause minimum damage to the holes as they screw into place.

The head design of a nail is very important. The large heads of common nails are able to carry withdrawal loads without pulling through the top member. Small-headed finish nails on the other hand pull through the top board. A joint with finishing nails can be improved by increasing the diameter or adding the number of nails if there is space.

· Wood screws

The key to maximum holding power is pre-boring pilot holes for both the threaded screw and the shank. Woodscrews are designed for holding power in terms of stress application relative to the grain direction. Most woodworkers acknowledge the importance of wood screws over other fasteners.

There are numerous fasteners available for wood joints; they include clamps, corrugated fasteners, and staples. Others are the third party which is fastened to nails and woodscrews. Examples of third-party fasteners include mending plates, flat corner irons, T-plates, and hinges.

Gluing Joints

Gluing includes joining wood using a chemical adhesive such as animal hide glue, aliphatic resin glue, or epoxy to create furniture, sporting goods, and structures. There are various types of glues favorable to woodworkers and each has its own special application procedures and performance features. Some common glues are white glues e.g. polyvinyl acetate emulsions or (PVA).

Yellow glues or (modified PVA) are considered to be better than white glues. This is because they hold up strong and are heat resistant. More recent glues are polyurethane glues and cyanoacrylate glues. Other special-purpose adhesives range from contact cement, hot-melt glues, and mastic and construction adhesives.

It is easy to understand how dovetails or woodscrews work. However, when it comes to glue joints things are different since we cannot physically observe whether the joint is strong or weak over time. The vast array of glues out there consequently gives rise to a misconception that ‘some glues are better than others.

There is no such thing as an all-purpose glue, one glue cannot contain the attributes and capabilities of all glues. Every wood glue plays a certain role when it comes to woodworking and as long as your wood piece remains dry and temperatures remain up to standard, glues hold up well.

Best Method For Joining Wood: A Summary

We have considered some of the best methods to join wood and their examples i.e.

- Worked or fitted joints e.g. mortise-and-tenon, dovetail, miter, and dowelled joints

- Fastening joints e.g. nails and screws.

- Glue joints.

So what is the best method of joining wood? Every joining method should fulfill two important requirements, which are:

- A joint should support the load of other parts.

- A joint must let the wood move as it expands and contracts over time. If the joint is glued or fastened as most are it should provide a suitable gluing surface, fastener, or anchor.

Use any type of joining method that fulfills the above requirements. You can also make a good joint by combining two or more of the discussed methods.