When it comes to woodworking, joining pieces of wood is a critical process. It’s important to choose the right type of joint, based on the intended use of the project, the type of wood being used, and your personal preference. However, one factor to consider when selecting a joint is its strength and adaptability. This is because any furniture made will experience mechanical stress throughout its existence and we want to make that the type of joint to use will be reliable. We, therefore, would want to choose the strongest method for joining wood.

Nevertheless, with numerous methods for joining wood, each with its unique advantages and disadvantages we may wonder how we can tell which joint is strong. Therefore, testing different types of wood joints is required to understand which one is strongest for your project. However examining joints can be a huge task, but this article will simplify the workload.

The Strongest Method for Joining Wood

To determine which joint is strong, we analyzed the research which was done by the Fine Woodworking team that had tested out a few joints to see how much racking pressure each joint could withstand.

Testing Joint Strength

The research was done by placing the joints under a servo-hydraulic press where racking can be stimulated. The hydraulic press has sensors that will measure the amount of racking pressure each joint can withstand.

The tested joints included the Mitres, Half lap joints, Mortise and tenon, Beadlock, Sub tenons joints, Butt joint and the Cop-and-stick joint. The results were shocking because it was very different from our popular belief.

Though some joints like the mortise-and-tenon joint are recognized as the strongest, the test results proved different. The half-lap joint was actually the strongest joint as it could withstand 1603 pounds of racking pressure, while the bridle could stand 1,560 pounds. The third joint was the mitre which could stand 1,374 pounds, followed by the Beadlock which could stand 836 pounds of pressure. The cope-and-stick joint supported 313 pounds while sub-tenons only supported 200 pounds.

Therefore looking at all these joints that were scrutinized in the angle of stronger than then the other, the half lap joint is actually the strongest method of joining wood. It is followed by the bridle and the mitre joint.

However, the result doesn’t render the other joints useless. Not all applications require great strength (e.g. picture frames and cabinet doors). Therefore knowing where to use these joints in your woodworking projects is key to good craftsmanship. One thing to remember is that even the strongest joints have their vulnerabilities.

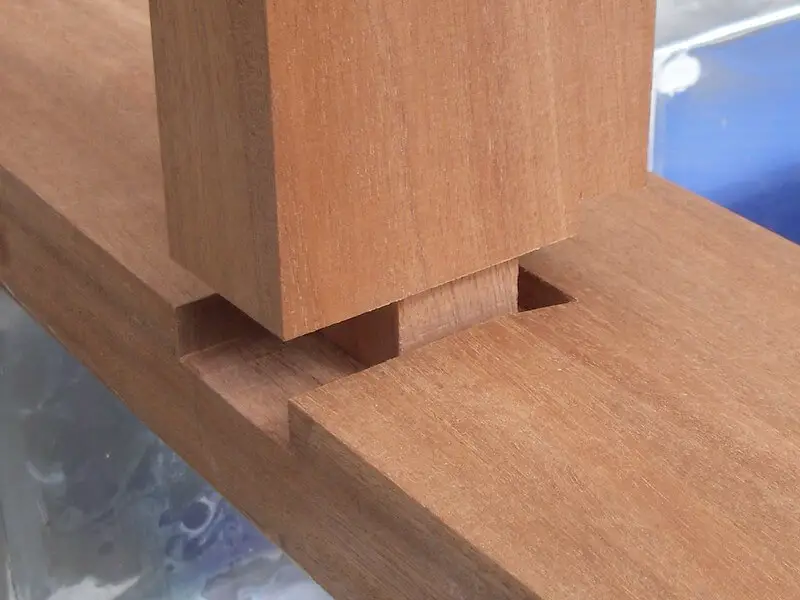

The Half-Lap Joint

A half-lap joint is made up of two pieces of wood, and half of the thickness of each piece is removed. Then the pieces are joined together, to create a thickness equal to the rest of the wood. It’s used to construct face frames, doors, tables, chairs, and frame-and-panel assemblies.

how strong is a half-lap joint?

The strength of a half-lap joint depends on the length of the joint and the thickness of the wood you will be using. When you properly construct, a half-lap joint it becomes a strong and stable joint that provides excellent support for woodworking projects.

half lap joint strength

The half-lap joint’s huge glue surface area and interlocking structure are two factors that make it the strongest. The larger surface area enables proper glueing, which significantly strengthens the adhesive bond between the joining surfaces. Additionally, the interlocking structure of the joint increases its resistance to separation and prevents lateral movement.

What Is A Stressed Joint?

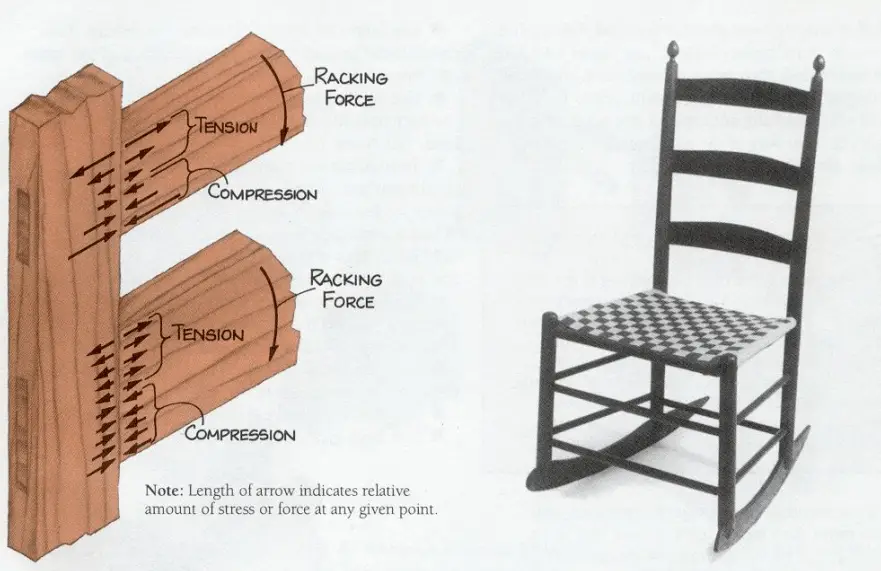

Racking is one way of stressing a joint, it can naturally occur through gravitational pull. Over time, gravity pulls the wood and bends it into a parallelogram shape creating diagonal stress across the joints. This mostly happens to a cabinet or drawer door.

Other joint stresses are caused by external pressure e.g. leaning on the chair, which causes intense pressure on the post-to-seat rail. When a table leg is hit from any direction, it causes a leg-to-apron joint. Over time these kinds of forces mostly cause actuator displacement.

Common Flaws in Strong Joint

- Though strong, the half-lap and bridle joints are exposed and might not look good on every project. Half-laps must also be clamped in many directions to squeeze and align the parts together.

- The mitre is vulnerable to wood movement, and unless reinforced with spline tips, it may start to pull apart over time. The mortise-and-tenon has an advantage over it, because of its inbuilt mechanical strength.

- Since Beadlocks are categorized as mortise-and-tenon joints, they easily keep parts aligned during glueing.

How to Make Wood Joints Stronger

All joints have vulnerabilities, but here are a few tips to strengthen them.

- Use a spline to strengthen the mitre

Mitre pieces are cut at a 45-degree angle, which contracts and expand over time. These changes cause joint failure in the outside corners. Adding splines creates long-grain surfaces preventing them from failing.

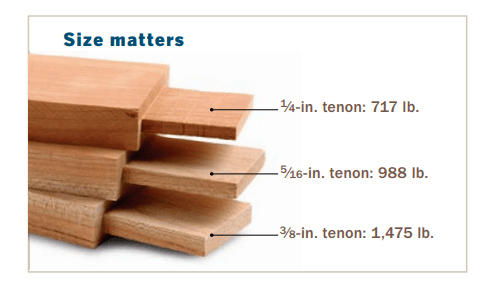

- Use a thicker tenon

Thick tenons are better when using wedged, pinned, or floating mortise-and-tenon. Size increases the strength of the structure. For example; inch tenons support 1475 pounds while inch tenon only supports 717 pounds of racking pressure.

- Use shop-made tenons instead of store-bought ones

Manufactured dowels and tenons are easy and fast when you’re not working on bulk projects. When using your shop-made tenons, ensure to make them longer.

- Glue panels to sub-tenons

Sub-tenons and cope-and-stick gain strength when glued panels like plywood are used for reinforcement.

- Create a broad glue surface to reinforce bridles and half-laps

Half-lap joints can support bulk projects. This joint has a broad glue surface that enables it to withstand intense racking forces.

- Use pocket screws to reinforce the butt joint

Butt joints can only support 473 pounds of racking pressure. Adding pocket screws can increase its load capacity. This type of joint is more suitable for the hidden interiors of a frame.

Summary

So which is the strongest joint? When it comes to withstanding racking pressure, the half-lap and bridle joints take the lead.

To make strong and durable furniture, you will need to frequently practice joinery. However, there are a few things you should consider when selecting or making a joint. These factors include;

- How will the joint look ( i.e. will the joint be hidden or exposed)

- How long will the furniture endure frequent movement

- What mechanical resistance will be applied to ensure the furniture lasts longer

- If the method of joinery is easy to assemble

- How and will it be used (e.g. will it be used as a picture frame or as an apron-to-leg joint)