When it comes to more advanced woodworking, you must up your game by investing in shop machines. They are a significant step up from hand tools as they offer more precision, speed, and versatility. Nevertheless, shop machines may be different starting points for beginner woodworkers, but with practice and patience, they are a big step up. Some of the primary shop machines we shall pay attention to are table saws, planers/jointers, bandsaws, and routers.

The Top 4 Must-Have Machines for Your Shop

If you’re a woodworking enthusiast looking to build your perfect workshop, you know that having suitable machines is crucial. Therefore, look at the essential machine tools you should have in your shop.

Table saw

A table saw is the workhorse of woodworking. In its basic form, a table saw consists of a flat table from which a rotary saw blade protrudes in the center. It is one of the most potent and versatile machines that no woodworking shop should lack.

Fitted with fences and guides, you use the table saw primarily to cut solid lumber and artificial boards to your preference. You can either cut through ripping or crosscutting. It is the first machine a woodworker should buy, as it becomes the centre of machine shop activities. You will use it to cut all types of joinery quickly and accurately, from dovetails and grooves to tenons, dadoes, and even mitres.

Though some modern table saws are made of aluminum, in most cases, the majority of table saws are built with heavy cast iron tables and folded steel plates. A typical modern table saw also contains a blade that can be lifted, lowered, or inclined and a side fence to guide the workpiece. Most models feature a sliding table with a tiltable edge, allowing woodworkers to cut compound angles. A panel saw is needed to cut large boards, such as those used for fitting furniture. It is similar in design to the table saw but has a sliding table that performs long cuts and a side carriage large enough to carry sizable boards through the saw.

In the world of table saws, three main versions are used.

- Benchtop table saw: These table saws are compact and are usually for lighter-duty jobs. They’re made to be portable, perfect for moving around the shop and conveniently storing them when you’re not using them.

- Cabinet table saws, the second class of table saws, are usually excellent for all-purpose work, from ripping to panel cutting. Their name comes from their motor being enclosed in a lower cabinet, with the belt driven by a belt and pulley system. They are the preferred table saws for many beginners.

- Contractor table saw: This third-class table saw has the tightest design. They are usually used by building contractors as they are quick and easy to cut on a job site where time and space are plentiful.

The choice of either table saw depends on the size of the work you will be doing, the size of your shop, and your preference. You might want a fixed table saw that will stay in one area of your shop or a portable one that you can move around the shop.

Planers

After purchasing a table saw, you need a machine that can plane and accurately smooth wood surfaces on all four sides. For home woodworkers, the best player is the one who can both plane and add thickness. Otherwise, if you get only a planer for addressing a workpiece’s face side and face edge, you will need a separate machine for thickness. The thickness plane plains the remaining surfaces parallel to the face side and edge.

A series of knives achieve the cutting action by bolting together in a rotating cutter head, with the number of blades ranging from two on small domestic models to six on large industrial machines. The cylindrical block with two to three balanced knives revolves rapidly to produce a smooth surface.

Band Saw

The bandsaw is the best machine because it is easy to use, versatile, and only takes up a little space in your shop. You can perform ripping, crosscutting, and even resawing with little instruction. Unlike the table saw, you can use the band saw to cut curved pieces and do deep ripsawing and resawing.

Bandsaws consist of a flexible steel blade that runs around two (or sometimes three) wheels in a continuous loop. The edge passes through a table that holds the workpiece. These blades are available with various tooth counts, measured as teeth per inch (TPI) and in multiple widths. In general, the more teeth a knife has, the finer its cut will be, and the narrower the width of an edge, the smaller the radius of the curve it will cut.

They are usually available in various sizes, but most woodworkers prefer a narrow bandsaw. Nevertheless, there are also wide bandsaws, but they are reserved for special projects.

Routers

The router is an excellent tool to have and the most versatile power tool. You can use it in almost every aspect of woodworking, besides assembly jobs. In extreme cases, when you use it creatively, you can prepare rough-cut lumber for a project, shape the pieces, cut the joinery, and embellish the finished assembly with decorative edge profiles.

It uses bits to perform a wide range of cutting and shaping tasks. In principle, all routers are built similarly, where a bit is mounted directly below a motor housing fitted with a handle on each side, and the whole assembly sits on a roughly circular base through which the bit protrudes.

Two routers are available: The plunge router and the standard router. The traditional router is suitable for edging work and is easy to use when you mount it on a router table. On the other hand, the plunge router has a spring-loaded base that allows you to position the bit above the workpiece and plunge it to an exact spot. Plunge routers are primarily well-suited for making mortise and tenon cuts.

Most routers have a fixed no-load speed, varying between 22,000 and 26,000 rpm. However, expect that a high rate of around 26000 rpm would only be required to produce a clean finish under extreme circumstances. Consider using high speed, especially when the bit encounters hardwood because the rate drops considerably.

The motor size of routers varies from router to router. The majority, however, range from 1/2 to 3 HP. However, consider choosing a router rated at 1,1/2 HP or more for general-purpose routing. The larger ones will maintain a high cutting speed without strain.

Brief History of Shop Machines

In the vibrant world of woodworking, shop machines have a rich history. They’ve been a crucial part of the carpentry landscape for centuries, shaping, carving, and smoothing our world one piece of timber at a time.

The story of shop machines began in the late 18th century, when the Industrial Revolution was in full swing, and inventors were pushing the boundaries of what was possible. One of their remarkable inventions was the machine they designed to shape wood automatically; thus, it became the first shop machine. From that humble beginning, shop machines evolved rapidly. In 1818, English inventor Samuel Bentham invented the first planing and slotting machines. This move was a game-changer, allowing woodworkers to produce consistent, high-quality work much faster.

As the 19th century rolled on, shop machines grew more complex and efficient. The advancement was evident in the invention of circular and band saws, which offered unprecedented precision and speed. Fast forward to the 20th century, and the advent of electricity brought yet another revolution. Power tools became the norm in woodworking shops, drastically reducing the time and effort required to create beautiful wooden pieces.

Today, the world of shop machines is incredibly diverse, with tools available for every imaginable woodworking task. From table saws to drill presses to CNC routers, these machines are a testament to human ingenuity and our enduring relationship with wood. Therefore, as technology advances, who knows what the future holds? So the next time you switch on your woodworking machine, remember its rich history. It’s not just a tool; it’s a piece of a centuries-old tradition of craftsmanship and innovation.

Picking your best shop machine set

There are a variety of brands on the market for your shop machine that you can choose from. Since we have mentioned several shop machines, we will only suggest the best brand for the most versatile machine to get you started on the right footing.

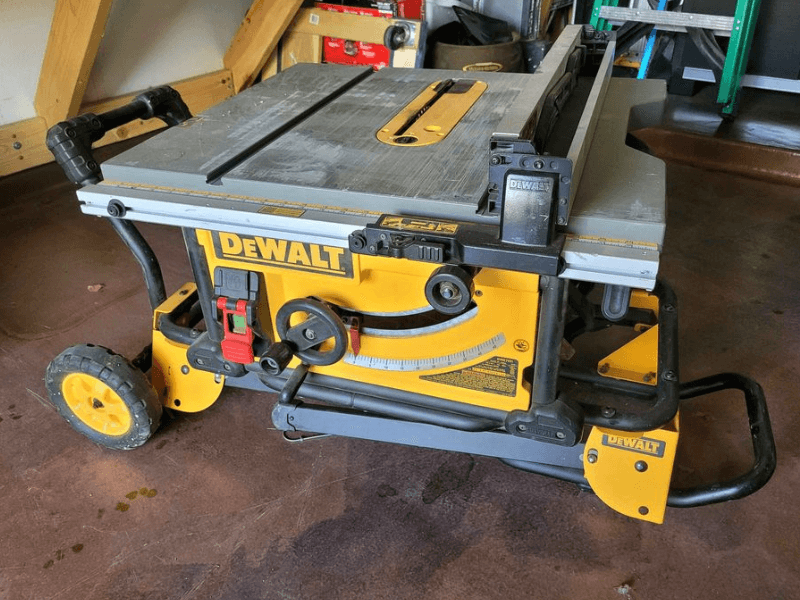

DEWALT DWE7485WS

A table saw is one of the most helpful machine tools in every furniture maker’s workshop. It is the most versatile, as it enables cuts to be made with precision. There are various models on the market with multiple sizes and valuable features that you can choose from. Nevertheless, one of the best table saws that is excellent for woodworkers looking for a powerful and compact table saw that can handle a wide range of materials is the DEWALT DWE7485WS.

We chose the Dewalt table saw as one of the best for our small shop. It's an excellent choice for woodworkers looking for a powerful and compact table saw capable of handling a wide range of materials.

Having worked with several other table saws, when compared with the DWE7485WS, it is an exceptional table saw. It is superior to other table saws, especially for beginners, mainly due to its advanced safety features. Additionally, it is compact, lightweight, and loaded with other friendly features. Therefore, this table saw will handle all your beginner’s needs and grow with you as you hone your skills.

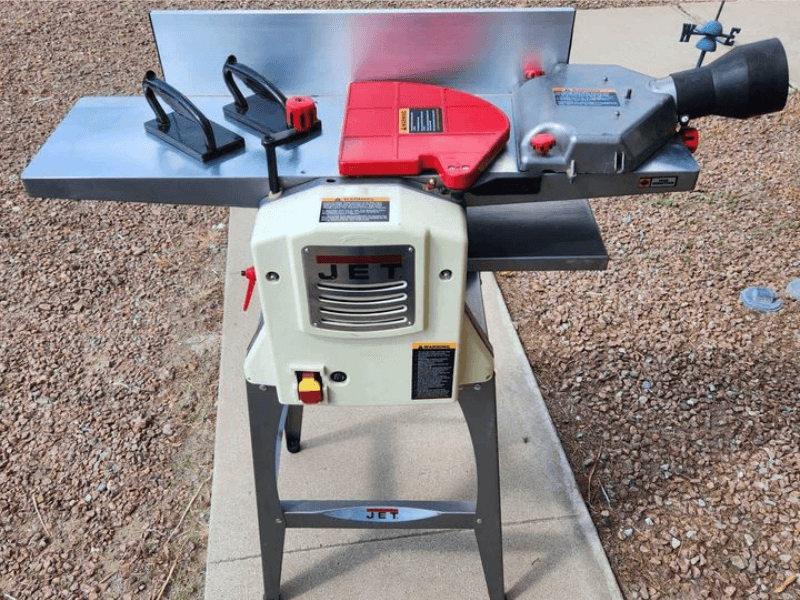

JET JJP-12, 12-Inch Planer/Jointer

The second class of shop machines that is also versatile is the planer. It will enable you to flatten and square timber sections for projects. However, a combination planer that can both plane and thickness should be your go-to to save space in your shop.

The JET JJP-12 is one of the best jointer-planer combos, especially for beginners and as an all-around shop machine. Over the years, Jet has been producing a range of high-quality machines for woodworkers, and its 12-inch Planer/Jointer model proves their work. This Planer/Jointer offers a sturdy body, tremendous power, and a reputation for quick and straightforward function switching.

The decision of whether to purchase a jointer or a planer initially is one that frustrates woodworkers frequently. The fact that these devices work together to dimension, square, and smooth the wood makes that decision more challenging. However, the new JET JJP-12 Jointer-Planer solves this issue and provides both capabilities in a precise, robust, and cost-effective package for your shop.

It also features a 3-hp motor that drives the three steel knife cutter heads at 5,500 rpm, with a maximum depth from a single pass of 1/8 inch. The engine can supply consistent power to the cutter head used for jointing and planing operations and the feed roller system in planer mode.

Last but not least, to make the JET JJP-12 Jointer-Planer as capable as it is versatile, the jointing and planing width capacity is a full 12″. Therefore, that capacity allows you to work with wider boards without having to rip them down to fit jointer widths in the 6 to 8″ range.

Conclusions

As we wrap up this guide to essential woodworking machines, we hope you feel inspired and ready to build your dream shop. Remember, suitable devices can make a difference in your woodworking projects, making them more accessible and enjoyable. Therefore, whether you’re a beginner or a seasoned woodworker, investing in quality machines is essential for achieving professional results.

Nevertheless, remember, the top 4 must-have machines we discussed are just the foundation of your shop. Depending on your specific woodworking needs and preferences, there may be additional machines that you find valuable. Feel free to experiment and add machines as you go along.

FAQ

What if I have a small budget to invest in all the machines?

As a beginner, you can only buy some shop machines at once. Therefore, you can start small and gradually build your woodworking machine collection as needed. You can begin with the essential devices, such as a table saw and a Planer/Jointer, and then add more as you go along. Alternatively, you can look for used engines or consider borrowing from a friend or a local maker space to save money initially. Remember, it’s all about being resourceful and maximizing what you have.

How do I choose the right size for machines like a jointer or a band saw?

As a rule of thumb, when choosing the size of a machine, always consider the size of your projects and the space you have available. A compact jointer or a benchtop band saw should be enough if you typically work on smaller projects. However, a giant machine with more power and capacity might be better if you work on larger projects or have a spacious shop. Therefore, it’s up to you to take measurements and do research to find the perfect size for your needs.