When it comes to applying polyurethane, selecting the right brush can make a significant difference in achieving a smooth and flawless finish. Foam brushes and bristle brushes are the two primary options to consider. In this article, we’ll explore the advantages and considerations of each brush type, taking into account the type of polyurethane—whether water-based or oil-based—and provide tips for minimizing common issues such as brush strokes and air bubbles.

Foam Brushes:

Smoothness and Ease Foam brushes are an excellent choice for applying polyurethane when aiming for a smooth finish with minimal brush strokes. Here are the key benefits of foam brushes:

- Smooth Finish: Foam brushes excel at leaving behind fewer visible brush strokes on the surface, resulting in a smoother appearance.

- Easy Cleanup: Foam brushes are typically disposable, allowing for quick and hassle-free cleanup after use. No need to worry about tedious brush cleaning or potential contamination from previous finishes.

- Even Application: Foam brushes offer consistent and even application of polyurethane, reducing the likelihood of pooling or uneven distribution on the surface.

While foam brushes provide several advantages, it’s important to be mindful of potential air bubble formation during application. However, by employing a careful technique and taking necessary precautions, such as applying thin coats and lightly tipping off bubbles, you can minimize their impact on the final finish.

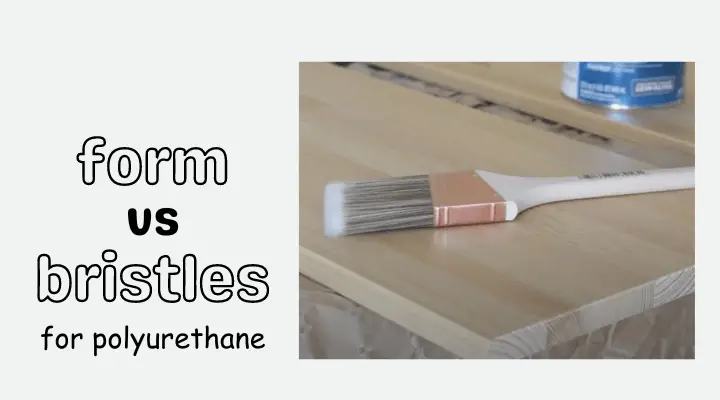

Bristle Brushes:

Control and Versatility Bristle brushes, available in various sizes and bristle types, offer versatility and precise control when applying polyurethane. Consider the following advantages of bristle brushes:

- Versatility: Bristle brushes come in a wide range of sizes and bristle types, including natural and synthetic bristles, providing flexibility to suit different project requirements.

- Control: Bristle brushes allow for better control over the flow and application of polyurethane. Their flexibility and texture enable precise maneuvering, making them ideal for detailed surfaces and edges.

- Durability: Quality bristle brushes, especially those with natural bristles, can withstand extended use with proper care and cleaning, making them a cost-effective option.

However, keep in mind that bristle brushes may leave behind visible brush strokes on the polyurethane finish. To minimize this effect, apply the polyurethane in the direction of the wood grain and use thin coats for a more seamless appearance.

Read Next

• https://improvewood.com/foam-brush-vs-bristle-brush-for-polyurethane/

• https://improvewood.com/best-brushes-for-polyurethane/

• https://improvewood.com/how-to-clean-polyurethane-brushes/

• https://improvewood.com/how-to-clean-polyurethane-floors/

• https://improvewood.com/types-of-wood-stains/

• https://improvewood.com/best-clear-coat-for-painted-furniture/

Choosing the Right Brush for Different Polyurethane Types:

The type of polyurethane—water-based or oil-based—also influences the choice of brush bristles. Here’s what to consider:

Water-Based Polyurethane:

Foam brushes are well-suited for water-based polyurethane due to their ability to handle thinner consistency without excessive absorption. Bristle brushes with synthetic bristles are also suitable, as they resist water absorption and maintain their shape for better application.

Oil-Based Polyurethane:

When working with oil-based polyurethane, foam brushes are not recommended due to their tendency to absorb the thicker product. Natural bristle brushes, such as those made from China bristle or hog hair, are the preferred choice, offering greater product retention and control.

Conclusion: Foam brush vs bristle brush for polyurethane

In summary, choosing between foam brushes and bristle brushes for polyurethane application depends on personal preference and specific project requirements. Foam brushes provide a smooth finish with minimal brush strokes, while bristle brushes offer control and versatility. Pay attention to the type of polyurethane being used, ensuring compatibility with the chosen brush type. Remember to use proper application techniques, such as thin coats and light tipping off of bubbles, to achieve the desired finish.

By selecting the right brush and applying polyurethane with care, you can transform your woodworking projects into stunning masterpieces with a flawless and visually appealing finish.