One of the prominent age-old debates in the woodworking fraternity is that of Maple vs Walnut wood. Having captured the hearts of DIYers and craftsmen for centuries, these majestic woods are two of the most commonly used timber varieties in the industry. However, they are dissimilar since each offers its distinct benefits and charms.

By definition, maple and walnut are domestic hardwoods. Their differences, however, allow for different offerings and capabilities between the two. As such, we will compare the two wood species to ascertain which is best suited for your next project.

New to woods? Check out Guide on Wood an advanced analysis on lumber

What is Maple Wood?

Maple wood is a product of the Aceraceae genus. There are around 120 species of this tree, with the majority found in parts of Asia and the rest distributed across northern Africa, Northern America, as well as Europe. Only the Acer laurinum is found in the Southern Hemisphere, which includes Antarctica, South America, and Australia. Locally, this wood is primarily found in the northeastern terrain and is commonly referred to as sugar maple, hard maple, or rock maple.

When it comes to harvesting, maple goes against grain as it is mostly sourced for its sapwood as opposed to its heartwood. This sapwood comes in an off-white creamy color, with a mild touch of golden or brown-reddish hue.

It also features straight grains and a fine, even texture.

Maple Wood Types

This wood is found in two main types, namely:

Hard or Rock Maple

In its tree form, this type of maple is commonly referred to as sugar maple. Hard or rock maple are its wood form. It is hailed as one of the densest domestic hardwoods, with a significant Janka hardness rating of 1450 lbf. Expectedly, this is the most commonly used maple wood type among woodworkers.

Soft Maple

This term refers to all other maple tree species, apart from hard/rock maple. As the name suggests, they are not half as dense as hard maple.

Soft maple is available in either big leaf or silver maple varieties. The latter is found in eastern North America and is renowned for its unique silver undertone. Inversely, big leaf maple is grown in Pacific Northwest’s coastal terrain and its tree is known for its gigantic leaves.

What is Maple Wood Used For?

Baseball Bats

Due to its density, maple is the primary wood used in making baseball bats for Major League Baseball.

Flooring

Due to its durability and strength properties, maple wood is often used for high traffic flooring such as bowling alleys, basketball courts, residential apartments, and dancing floors.

Musical Instruments

Maple’s visual aesthetic and tight grain structure also makes it an ideal material for making musical instruments.

Woodworking

Lastly, this wood is also used for general woodworking undertakings including cabinetry, furniture, workbenches, and cutting boards.

Advantages of Maple Wood

Availability

Maple wood is abundantly available, particularly for commercial use, in the United States as it is sustainably harvested. For this reason, the wood is also very affordable.

Aesthetics

Its straight wood grains and uniform light color makes it visually appealing. What’s more, it takes dark stains well, thus can also be used to mimic the more costly and darker wood varieties.

Strength

It is ultra-durable on account of its sturdy nature. It is very sense and extra strong.

Disadvantages of Maple Wood

High Sensitivity to Heat and Humidity

Like most hardwood varieties, maple is highly susceptible to warping or splitting due to humidity or temperature-induced contraction and expansion. Therefore, it is not suitable for areas prone to intense summer humidity.

Staining

Its tight grain causes the wood to take in stain irregularly, bringing about blotches. As such, you might have a hard time using pigments on this wood.

Your options include using gel stain, a toner, or pre-conditioner to attain a more even finish. Alternatively, you could choose to stick with the wood’s natural aesthetic.

Density

Commonly described as ‘wickedly strong’, maple’s high density can prove to be a headache for many as it limits the wood’s workability. This feature makes it somewhat hard to work with, particularly with hand tools.

What is Walnut Wood?

Walnut timber is harvested from trees in the Juglandaceae family. It dates back to the Old World (Afro-Eurasia starting from the 1500s) and is still very relevant in the contemporary New World. Ideally, walnut has stood out as a superior hardwood variety for centuries, so much so that American colonists exported this wood to England as early as the 1600s to be used in the small-arms and fine furniture industries.

It features straight wood grains, moderate luster, and medium texture. Its pores are semi-ring, with early wood pores being slightly larger than their latewood counterparts.

Notably, walnut is largely prized for its workability. In addition to its straight grains, this wood has immense dimensional stability and shock resistance. While maple’s super-strength makes it somewhat rigid and less easy to work with, walnut’s Janka hardness of 1010 lbf coupled with its dimensional stability give it sufficient strength and bending properties, making it a joy to work with.

By and large, it is almost impossible to overstate walnut’s popularity among local woodworkers. This wood is acclaimed for its strength, shock resistance, and dimensional stability properties. To cap it off, its dark brown, chocolaty color gives it a unique aesthetic outlook, so good-looking that it needs no staining.

Walnut Wood Types

Black Walnut

This is the most dominant walnut variety available in the United States. If you have ever purchased walnut locally, nine times out of ten it was black walnut. Its trees originate from the country’s eastern hemisphere.

English Walnut

This walnut variety is also known as European walnut as it grows in various parts of Europe. Compared to black walnut, English walnut has a paler milk chocolaty hue.

Also noteworthy, this is the strongest type of walnut. It has a Janka hardness rating of 1220 lbf.

Interesting Fact: English walnut is the most common source of edible walnuts globally.

Claro Walnut

This variety grows in walnut orchards located in Claro, Oregon, and California. Being orchard-grown, this wood is flooded with irregular wood grain patterns.

Butternut

Contrary to popular belief, butternut is also a part of the walnut species. It is commonly referred to as the poor man’s walnut. However, this pejorative is somewhat misleading. Butternut is an alluring wood as it comes in a beautiful golden tan hue. It is also very easy to work with, especially for small projects, mostly due to its 490 lbf hardness rating.

What is Walnut Wood Used For?

Fine Woodworking

Due to its characteristic dark tone and attractive wood grains, coupled with its sturdy nature, walnut is commonly used to make high-end pieces of carpentry and furniture, such as carvings, expensive furniture, and trims.

General Woodworking

It is also used for regular woodworking undertakings such as cabinetry.

Musical Instruments

Its strength and aesthetic appeal also make walnut ideal for making musical instruments. It is specifically used for piano and guitar soundboards.

Gunstocks

Walnuts density, resilience, and hardness mean it is less prone to shrinkage, splitting, and warping. Moreover, it is sturdy enough to withstand heavy impact. Therefore, it is used to make gunstocks as it can withstand gun recoils aptly and is durable enough for a gun’s lively activities.

Flooring

Its ability to withstand heavy impact allows walnut to be used for residential and commercial flooring purposes.

Advantages of Walnut Wood

Workability

Walnut’s is a joy to work with. It machines well, planes effortlessly, glues well, screws efficiently, and takes cutting edges well enough for intricate curves.

Color

Its dark chocolaty hue makes for a very appealing and unique outlook. In fact, this color is so good that it needs not staining in most cases.

Disadvantages of Walnut Wood

Costly

This premium wood costs an arm and a leg. In addition to its superior qualities, there are also concerns pertaining its sustainable harvesting, leading to its high price.

Photo-reactive

Although walnut’s chocolaty color is highly alluring, the wood tends to oxidize over time causing this color to fade to an orange-honey hue.

You can avoid this by using walnut in areas that are not exposed to direct sunlight or applying a sealer to protect the wood’s surface from UV rays.

Maple vs. Walnut

Both these hardwoods are strong, durable, aesthetically appealing, and relatively easy to work with. However, they are not identical. As such, let’s compare their properties to identify which of the two is superior to the other.

Appearance

Maple comes in a light off-white hue, ranging from pinkish yellow to white. Notably, it manages to maintain this color for a long period of time.

Walnut comes in a dark brown, chocolaty hue. However, since the wood is photo-reactive, this color oxidizes over time due to exposure to UV rays, fading to a honey-orange color. It needs maintenance to preserve this color for a long.

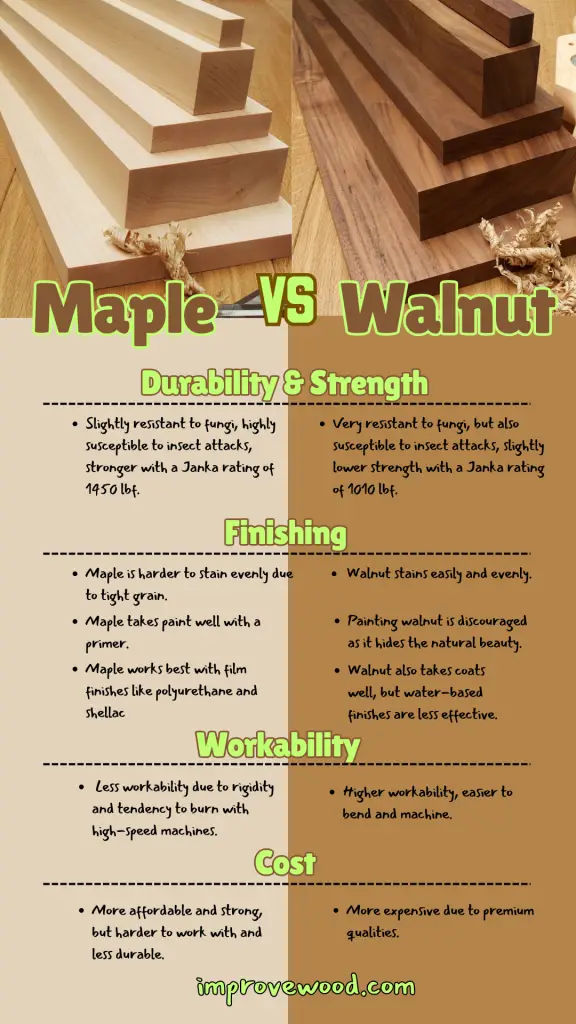

Durability & Strength

Maple is slightly resistant to fungi and highly susceptible to insect attack. This wood is commonly attacked by diptera, larvae of the Agromyza genus, which in turn cause pitch fleck on the wood’s surface. These are tiny bored holes. Fortunately, pitch flecks have little to no effect on the wood’s structural stability and their effect on its visual outlook is arbitrary.

Inversely, walnut is very resistant to fungi, making it more durable. However, it is also susceptible to attacks by certain insects, most notably moths.

In terms of strength, maple is arguably the better of the two. It has a higher Janka rating (1450 lbf compared to 1010 lbf), a slightly higher crushing strength, (7830 lbf compared to 7580 lbf), and a slightly higher modulus of rupture (15,800 lbf compared to 14,600 lbf).

Density

Their densities are more or less similar. Walnut has a density of 630kg/m3, while maple has a density of 650 kg/m3.

Finishing

-Stains

Staining maple can prove to be a major problem even for expert woodworkers given the wood’s tight grain. In this case, blotchiness is a major hurdle given the wood’s nature. The more tight-grained areas of the wood will let in less stain, leading to a lighter color. Inversely, the more coarse-grained areas will let in more stain, bringing about a darker stain. Blotchy stains will be more pronounced in the darker-stained sections.

In this case, gel stains are arguably the best option for staining maple. You have a higher chance of attaining an even finish with this finish since it does not need to penetrate the wood’s surface, and instead sits on the surface. However, with gel stains on maple, you do not expect to impart a dark color on the wood’s surface.

Dye stains are also a reasonably good option as they are capable of dark coloring highly dense woods like maple. When mixed with solvent, dye ionizes into very minute, electrically charged particles which are able to transport the color. As such, these extremely small particles carry the dye’s color deep into maple’s fibers, ensuring your wood gets an even color.

Alternatively, layered staining can give you the best of both worlds. Start by applying a water-soluble dye of your preferred color and let it sit until dry. This will emphasize the wood’s grain while also giving it a deep color. Then proceed to applying your pigmented stain (in this case gel stain). There is no need to seal between the two layers. The water-soluble dye will have colored the wood and opened up its pores, making it more receptive to the gel stain, ultimately evening out the color. However, the gel and dye stains should be of a similar color for layered staining to work.

Inversely, staining walnut is a straightforward undertaking. This wood’s medium-porous and smooth texture allows it to take in all manner of stains evenly for a crisp finish. However, you should note that walnut will retain its natural grain pattern given that its prominent pores will telegraph their natural structure using the colored pigments.

-Paints

Maple is one of the most common paint-grade hardwoods in the current market thanks to its flat and low-key grain texture. Therefore, it takes paint well. Nonetheless, you are required to use a shellac or oil primer before applying the paint. Priming the wood will ensure optimal adhesion of paint to the surface, while also adding to its durability. What’s more, a primer’s stain-blocking properties will prevent wood stains from bleeding through your newly applied paint coat.

On the flipside, woodworkers consider it a criminal offence to paint over walnut. It is like using ketchup on fillet mignon! It beats logic to paint this highly pricey wood and conceal its natural chocolaty appeal, while you can do the same to more affordable hardwood varieties, maple included.

-Coats

Maple is best coated with film finishes. The thickness of these finishes add depth to the wood, bringing out more of its character. Moreover, this thickness provides the wood with better protection than penetrating finishes from humidity and scratches. For purists who disapprove of adding color to wood, polyurethane is arguably your safest bet. Applying multiple coats of this solvent-based finish will provide your maple with a glossy non-yellowing finish, while also protecting the wood surface.

Dewaxed colorless shellac is another clear coat worth considering for maple. Despite being water white in color, shellac gives maple a unique chatoyance that brings out the wood’s curvy figure, adding some warmth to it. What’s more, since it is dewaxed, it can serve as a universal sealer. You can add extra topcoats once the shellac dries off. For instance, a coat of polyurethane can add more protection and durability to your wood.

Walnut also takes all coats reasonably well, with the exception of water-based finishes as they lack ample color. Some viable coating options for this wood include a blend of varnish and oil or film building finishes, including lacquer, varnish and shellac. Notably, if you are looking to add warmth to the wood, orange shellac’s hue is your safest bet.

Workability

It is easier to work with walnut than maple. Although both are quite strong, walnut’s combination of strength, density, shock resistance, and hardness make it the most appealing for woodworkers. It especially offers high elasticity and is excellent for bending.

Inversely, maple’s super-strength and density make it less appealing for bending as it is very rigid, leading to its lesser workability despite its higher strength. Maple’s lower workability also stems from its tendency to burn when exposed to high-speed machines, particularly cutters. The wood’s rigidity increases the risk of friction, thus the risk of burning.

Cost

Walnut is considered the premium choice, making it costlier than maple.

Verdict: Maple vs Walnut

As detailed above, walnut wood is more durable, especially in terms of fungi and insect resistance, has a higher workability, and has a more sought-after color, making it more attractive. However, you will have to pay a premium price for this premium timber.

In contrast, maple is more affordable and is also a very strong material. However, it is more difficult to work with, is fairly harder to stain, and is less durable.

Therefore, using walnut is more advantageous than using maple. Although both options offer good value for money, buyers with a higher budget would be better placed choosing walnut over maple.