If you have been in woodworking for a while, you may have heard the praise of Japanese carpentry and Japanese woodworking hand tools.

Japanese woodworking has been practiced for many centuries, and just like in any craft, such longevity usually yields a culture of innovation. Over the years, Japanese carpentry has developed tools and principles that make woodworking a more therapeutic experience.

If you’re just getting started in the Japanese art of woodworking, our article should guide you on the essential Japanese tools their spirit, and nature.

Something about Japanese woodworking

Nature, religion, and society are intricately entwined in Japan. Nobody understands this better than a woodworker, whose intellectual and spiritual convictions form the foundation of their trade.

All living things and living things, including wood, have a spiritual component according to Shinto, the native religion of the Japanese. Japanese woodworkers are compelled to cooperate with nature rather than fight it because of their faith in ‘animism.

Japanese woodworkers demonstrate their appreciation for nature in various ways, such as by using wood that has died naturally and honoring the curvature and irregularities of wood in its original state.

Traditional Japanese carpentry tools include chisels, mallets and hammers, saws, and Japanese hand planes.

Japanese woodworking tools starter set

Experience the artistry of Japanese woodworking with the KAKURI Japanese Woodworking Tool Set. Crafted with the highest-grade materials, these tools are the choice of professional craftsmen worldwide, including musical instrument artisans, joinery experts, furniture craftsmen, and carpenters.

The set features a range of essential tools, housed in a traditional paulownia toolbox known for its lightweight and durable nature.

What you get with this set

The set features a range of essential tools, housed in a traditional paulownia toolbox known for its lightweight and durable nature. Let’s explore the exquisite tools within this set:

- Japanese Pull Saw (Universal 10.5″): The special universal blade of this saw allows craftsmen to effortlessly perform both rip cuts and crosscuts, regardless of the wood’s grain direction. It enables versatility and precision in a wide range of carpentry projects.

- Japanese Pull Saw (Hardwood 8″): Designed to cut through various hardwoods like oak, sandalwood, mahogany, maple, walnut, and pine, this saw showcases exceptional performance. It effortlessly handles solid materials such as ipe and ebony, as well as old wood materials, laminated wood, and plywood.

- Japanese Woodworking Hammer: A vital tool for nailing and chiseling, this traditional Japanese hammer is meticulously crafted for precision and durability. It ensures accurate and controlled strikes, allowing for exquisite woodworking results.

- Japanese Block Plane: Achieve smooth and refined wood surfaces with this block plane. Its ergonomic design, coupled with Japanese craftsmanship, ensures ease of use and exceptional planing performance. Ideal for chamfering and finishing wood surfaces.

- Japanese Woodworking Auger: Make pilot holes and drill with precision using this essential tool. Crafted with meticulous attention to detail, it provides reliability and accuracy in your woodworking projects.

- Japanese Woodworking Square: Accurate measuring and marking are made easy with this traditional Japanese woodworking square. It guarantees precision and symmetry in your work, ensuring flawless results.

Comfort is paramount during woodworking, which is why these tools feature handles, grips, and plane bodies made of high-quality red oak. The ergonomic design, coupled with the hand-finished oak, offers a comfortable and secure grip, enhancing your woodworking experience with each use.

What sets these tools apart is the easy interchangeable blade system. The saw blades are replaceable and compatible with all blades and handles in the same series. Changing blades is a breeze – simply lift the locking mechanism, slide in the blade, close the mechanism, and you’re ready to embark on your project. No screws or tools are required for replacement, making blade changes quick and hassle-free.

Unlock the craftsmanship of Japanese woodworking with the KAKURI Japanese Woodworking Tool Set. Embrace the beauty, precision, and versatility of these meticulously crafted tools, and elevate your woodworking projects to new heights. Experience the joy of creating with tools that seamlessly blend tradition and innovation.

Read Next

- Best Japanese Wood Carving Tools

- A Beginner’s Guide to Skew Chisels

- Hand Plane for Beginners

- Best Woods for Carving Using a Dremel

- Jigsaw vs Bandsaw

Japanese Carpentry tools

Chisels

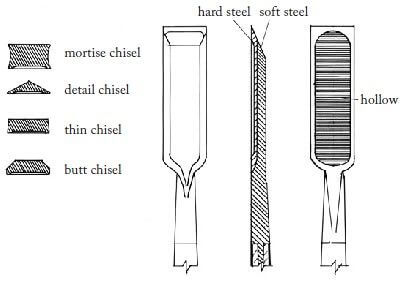

Most Japanese woodworking and woodcarving chisels are handmade or drop forged. Most of them are made with a ribbon extension fixed inside a handle. They may have a metal ring or not. The metal ring reinforces the area where the tung enters the handle. In socket chisel construction, the tongue is replaced with a cone that fits into a handle. It is tightly fitted and held into place by friction.

There are several types of traditional Japanese chisels. They include;

Oite chisels

They are general-purpose chisels that do most shop tasks. Typically, these thin blade chisels are between 2 and 3 inches long. These types of chisels are available in a variety of widths.

They have a top hoop for stringing. They include:

Atsu chisels

They can be compared to chisels, only happen to be much thicker and stronger. Both carpenters and cabinet makers use them for making large joints. Atsu chisels are available in 11/2 and 2 inches sizes. However, they can be narrower as 1/8 or wider.

Mukomachi chisels

These are meant for chiseling mortises and grooves. The blade is narrow with a neck as thick as the cutting edge, enabling the chisel to cut deep. The blade has a rectangular cross-section and slightly concave edges. It has the advantage of reducing friction when removing it from the mortise.

Tzuki chisels

These are paring chisels designed to be used by both hands. They are meant for cleaning mortises and smoothing joints. The blades are sharpened at a lower angle for effective paring than other chisels.

Japanese hand planes

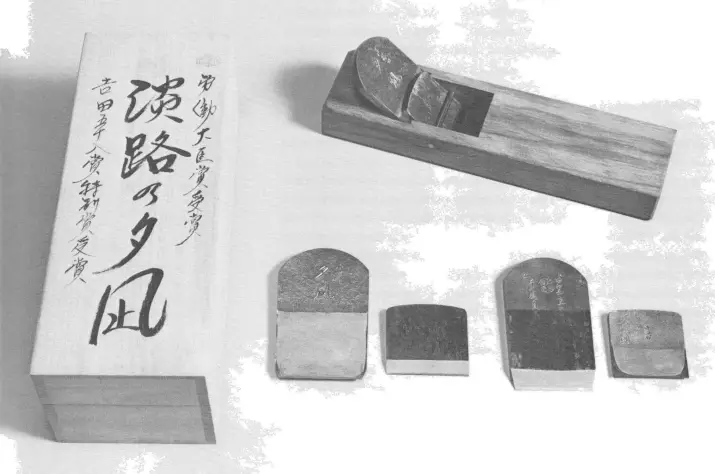

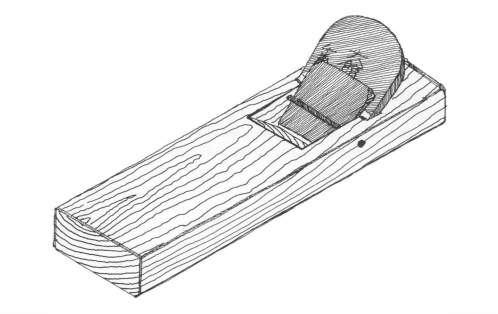

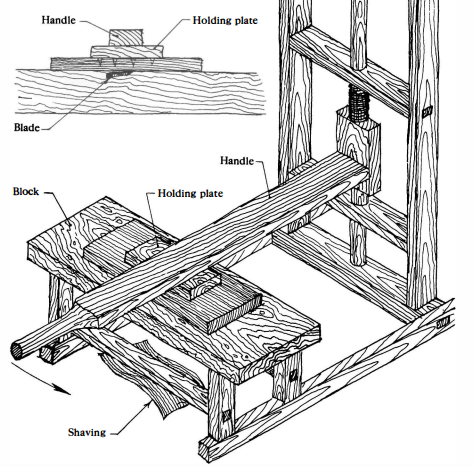

Planes are a recent introduction and the most widely used Japanese tools. Since sanding and finishing are hardly used, the onus is on the plane. The original Japanese planes have one blade and one bracket. The bracket was introduced later in 1900.

The planes come in a variety of forms:

- dai planes(plane block)

- hire Kanna(common plane)

- Tachi-har-Kanna( standing)

- Kashi- bar-Kanna(reversed bar plane)

- kiwa Kanna(corner cutting plane)

- Mizo Kanna (groove-making plane)

- shakuri Kanna(plow plane)

- Kukura Kanna (pointed side shaving plane)

- waki tori Kanna (side shaving plane)

- men-to Kanna(molding planes)

Dai planes

These are block planes made from solid wood. The plane blade was made by a blacksmith who purchased the blocks from Daiya shokunin (probably a place where carpenters made the blocks). The blacksmith would then fix the blade and deliver it to customers.

Hira Kanna

This is a common plane. We have different types of hire Kanna planes with slight differences. They include:

- herashi Kanna

- tira Shika

- chu-shiko

- jo-shiko

- naga-dai Kanna

Herashi Kanna

This plane removes waste from wood that is not big enough to be split. Planning is done across the grain to remove waste material from wide boards. Like the common jack plane, the blade edges are rounded at about 2mm. The curvature formed stops enabling the blade to make deep cuts when planning. As a result, the corners do not dig in and take steps when removing shavings from wide boards.

Tira shiko

They are roughing planes that make fairly deep cuts but not as deep as those made by herashi Kanna. The mouth of the pane is wide, and the curvature is much less. This plane is used with or without breakers. The blades are usually 60 or 65 mm wide.

Chu shiko

This is a smoothing plane. The blade is always used with a cheap breaker. It is used to remove roughness made by tira shiko. Its mouth is quite narrow to produce the smoothness required. The high-quality blade has a slight curvature.

Jo shiko

This is a smoothing plane compared to western plane no 4. The plane is also known as shiange Kanna. The plane produces very high-quality, shining, and smooth surfaces. It is the last plane to be used for any woodworking work. Since Japanese carpentry hardly involves sanding in finishing, this plane does the finishing. The blade is used with or without a cheap bracket. So much attention is paid to sharpness. The high-quality blade has a cutting edge that is generally straight.

Naga Dai Kanna

This is compared to western multipurpose jack planes. Cabinet makers prefer using this plane to make absolute flat surfaces. It has a longer sole which is effective for producing level surfaces. The blade is used with a cheap breaker.

There are two types of planes used for intermediate smoothing. One is finer than the other. Mostly used in shooting thin board edges.

Other types of Japanese planes

Tach bar Kanna

This plane is also known as a standing blade plane. Occasionally the blade is set at ninety degrees to the sole. The plane scrapes rather than cuts wood. No cheap breakers are necessary with the blade of this type of plane.

Kaeshi bar Kanna

Used when planning hardwood and softwood with stubborn or intertwined grains. It’s set in such a way that there is no space between the mouth of the block and the cutting edge.

Kuwa Kanna

They are corner-cutting planes. They may or may not be used with chip breakers. The blade is angled so that one side of the cutting edge does not protrude above the plane’s sole. The sole can be prepared so that it does truing, roughing, or smoothing.

Mizo Kanna

They are generally meant to make grooves. The sole of the planes is usually the size of the blade. The grooves cut are the exact size of the sole. The blade can angle like the kiwa Kanna plane. The chip breakers are used with the blades of these planes. Wedges may be placed behind the blade rather than in front.

Shakuri Kanna

This can be compared to the western plane, the plow plane. Mostly preferred by cabinet makers for cleaning the bottoms of grooves and making the size of grooves as well. The blades which are used with chip breakers are set at 45degrees.

Hakura Kanna

They have pointed side shaving. They plan narrow grooves and remove corners of dovetail keys. The plane can cut left and right. It is not used with cheap breakers. The shape of the blade is like that of a knife. It is slightly tapered from the back.

Waki tori Kanna

This is a side-shaving plane. It is like a shukuru Kanna but slightly wider. It is mainly used to clean the sides of wide grooves.

Men toh Kanna

These are molding planes. They are a recent introduction to Japanese tools. Their main function is to shave and size the corners of frames. Blades are used with chip brackets set at 40 to 45 degrees.

Japenese Saws

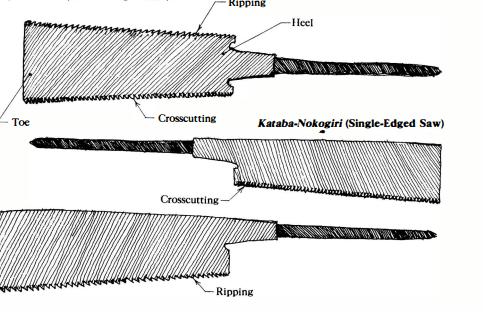

The origin of Japanese saws is china. These saws were crosscut in nature. The teeth of these saws are set to cut by the pulling action. They come in various types. The double-edged saw known as ryoba is the most common. They are also classified as ryoba or kalaba.

Ryoba nook

The saw does both cross-cutting and ripping.

Azebeki

Is a ryoba type of saws available in two sizes. Like all ryoba saws, its neck is narrow. has curved edges which allow the beginning of cuts at the centers of boards.

Anahiki nokogiri

This is a cross-cut saw capable of cutting logs and large beams. It is more of a kalaba than a ryoba. The saw has other names such as hanamaru, round nose, and Hana magari, which means bend nose.

Kamochiki nokogiri

This is a kalaba rip saw. It has a short body of about 8-10 cm in length. Its size enables the saw to cut deep straight cuts. It can be used for deep grooves in interior beams when used with chisels.

Kugihiki nokogiri

This is another kalaba type of cross-cut saw. Mainly used for trimming beams. Its 18cm long and has about 22 to 26 per 25 mm.

Duziki noko giri

It is a kalaba crosscut saw. With aback like western tenon saws. The strip of sheet steel or brass supports its thin blade. Its main function is to cut tenon shoulders. They range in length from 20 to 28 cm/. The number of teeth per 25mm ranges from 17 to 28 depending on the saw size.

Hosobiki noko giri

The 20 cm saw functions as a rip saw. It is used to cut chicks of minute chicks. The teeth are both crosscut rip-like. This cross breed of teeth makes it effective on hardwoods.

Shitagi noko giri

It’s a steel-backed saw like a duzuki. However, the blade is thicker and shorter. It’s 15 cm long and 25 cm wide. Its teeth are crosscut and are about 25 in number per 25 mm.

Mawa shahiki noko giri

It’s a corner saw used to cut large circles. Its top end is curled for its maneuvering of curves. Has a length of 20-25cm. The saw is 4 cm wide.

Osa Chiki noko giri.

It’s a minute saw that plays the role of conditioning other tools. It’s about 13 to 15 cm long with 22 to28 teeth per inch. The blade is about 2.5cm wide.

Teeth of Japanese saws

They are quite different compared to their western counterparts. Nevertheless, they play the same role as cross-cutting and ripping.

Cross-cutting teeth

The pointed teeth are shaped like knives. They cut and, at the same time, clear the kerfs.

Ripping teethestern

Those designed for ripping softwoods are angled so that they bite into the wood, whereas hardwood has added strength to prevent teeth from dipping, making it easier to pull.

Japanese Mallets and hammers

Unlike their western counterparts, which are entirely made of wood, Japanese mallets are made of steel. They are known as tsushi mallets. Hammer’s heads have either curved or straight handles.

These mallets are thought to have emerged at the onset of human civilization. Tsushi mallets come in various types and forms.

Types of hammers

Ryoguchi ASAR tsuchi

This Is a saw-set hammer. It has a tapered upper side for easy visibility when striking saw teeth. As would be expected, the head is thin and flat.

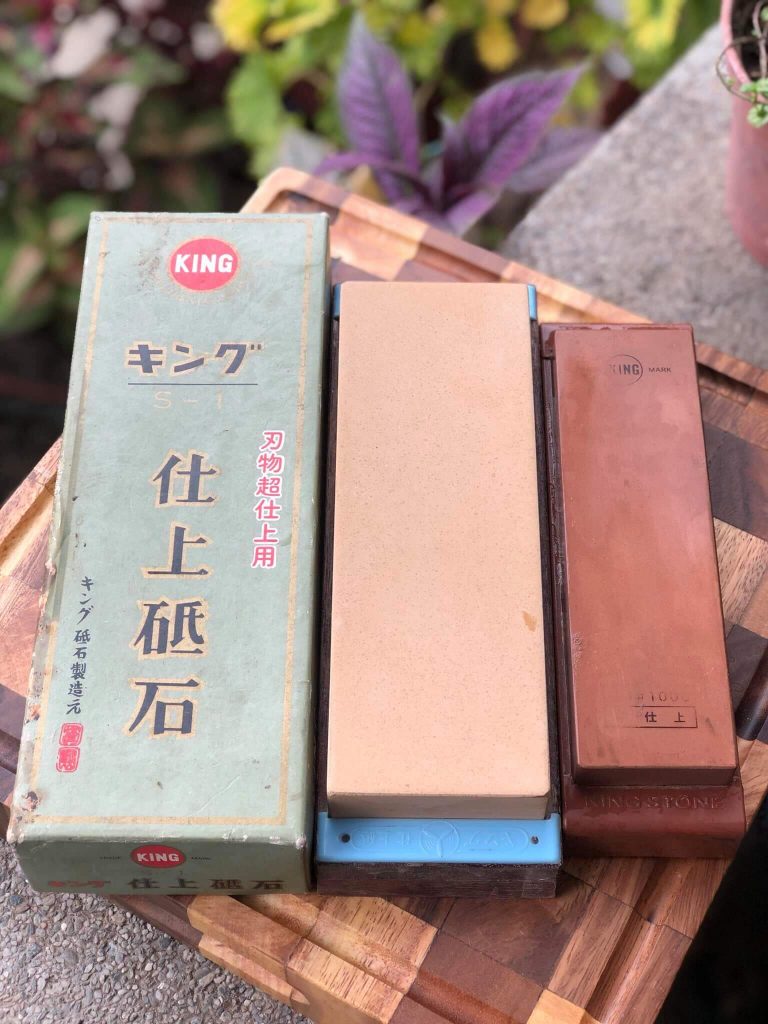

Japanese Sharpening stones

Japanese stones are probably as old as stone age tools. They are used with water instead of oil when sharpening edges. The earliest Japanese stones occur naturally. Manmade sharpening stones were introduced later on.

Japanese sharpening stones come in two categories, namely;

- natural water stones

- manmade water stones

Natural water stones

Kongosho do (carbonrundum stone)

They are course stones used to change the angle of blades. They remove streaks and nicks very quickly. However, it is not necessary to have this type of stone; again, it is too coarse to be used for honing.

Era do (course stone)

This is a natural stone. It removes small nicks and rough surfaces caused by kongosha do. Among other things, it does more to strengthen the cutting edge level. Like most natural stones, it is used with water when sharpening cutting edges.

Naka do (medium stone)

It’s used to remove streaks left by ara do. You can also start sharpening a dull stone into a fine, even cutting edge. For better results, sharpen until a burr is formed.

A wese do (finishing stone)

This is but a honing stone. It removes burr formed by medium stone. Honing on this stone produces a fine razor-sharp cutting edge.

Nagura -do (correcting stone).

It is a small carved stone. Sharpening stones get twisted, warped, and rough. It’s the work of a nagura is to correct these deformities. The stone straightens and removes hard particles that appear on the surfaces of the finishing stones.

Man Made water stones.

They are made from either synthetic materials or crushed natural stones. The synthetic ones are mostly metallic hard metallic oxides such as aluminum oxides and carbides. We have a variety of these artificial sharpening stones.

Types of man-made stones.

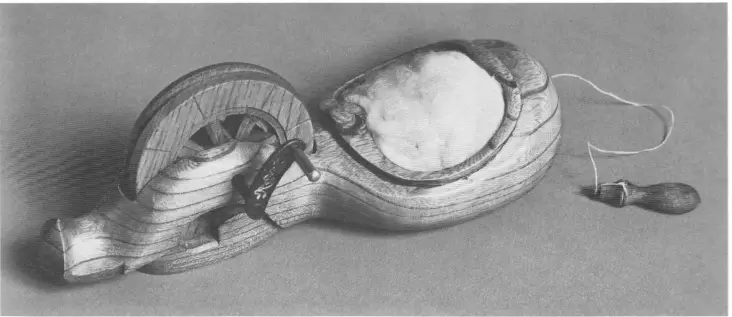

Japanese Marking tools

They are referred to as Sumetsuke- dogu in Japanese. They include:

Sumitsubo (ink pot)

–carpenters use this type of tool to make outlines of shapes of houses to be built and to mark out rails and stiles of doors. Sumitsubo makes lines that resemble chalk lines. However, fine silk and ink are used instead of course chalked string. A shukinin makes a sumitsubo himself. Old sumitsubo was made of mulberry wood.

Kaesh sashigane

-is equivalent to a western framing square though it is narrower and more flexible. They have the advantage of not smudging the ink. It is thought to have come from China.

Keshiki (marking gauge)-

they are homemade. We do, however, have Japanese kashekis in tool shops. They resemble their western counterparts but use blades instead of pins. We have different sizes, shapes, and types for different purposes. They include:

Suji kesheti-line marking gauge

Suji kesheti-for mortising

Ana- keshiki-mortise gauge( the only one that uses pins)

Kamasheki-sickle gauge is wholly made of steel i.e., the beam and the blade. Its function is to mark grooves and mortises.

Wari kasheki-also is known as splitting gauge as it splits softwood as deep as 3/4 an inch.

Bunimawashi-is a beam compass.

This tool is thought to have been used as early as the second century. Cooper’s bunmawashi is made of a wooden post on which a wooden beam slides. To change the radius, the beam is adjusted and wedged. The other type consists of a bamboo or wood bar drilled regularly. The radius is determined by inserting the tapered wire in the holes.

Shirabaki – this is a Japanese version of a marking knife. Its main function is marking across the grain, especially when marking tenon shoulders. A sherabaki looks like a Japanese regular knife only that the cutting edge angle is much greater. The greater angle makes the marking knife mark instead of cutting.

Makigane–

it is a small square. The Japanese pronounce the English word ‘square’ as sukoya. Now the makigane is also known as sekuya. The tool is generally used to check the squares of rails and stiles.

Kigata jogu–

These are block gauges that work as templates for marking angles. They are used for guiding saw cuts. Examples of kigata jogu include:

Tomegata-jogu-tome means 45 degrees

Unanori jogu-means riding a horse. Unanori jogu, in particular, is used to make joints that ride on other parts of the wood.

- Nama tomegata

- Tsubakuro tomegata are made from oak, known as keyaki, black persimmon, and steel.

- Jogi – is a bevel gauge. It is the same as the western type. The measurements differ slightly.

- Daikuno makigane-it is similar to a shashigane, only that it is a heavy-duty square that is thicker and more rigid. Its tongue is tapered from the outside edge to the inside to allow the outside edge to lay flat on the face of the wood during marking.

- Ogane-means a large square. In most cases, it is made at the construction site. It is used to check the string outlines.

Japanese woodworking hand tools: Summary

The Japanese have all categories of woodworking tools. They include marking tools, saws, chisels, planes, and mallets. Most Japanese tools originated from China, apart from the bevel gauge, which seems to have come from the west. The tools play the same function as their western counterparts. Nevertheless, the technique of using some tools differs. For instance, planning and sawing are done by pulling. Both ancient and current Japanese carpentry tools are available in the tools shop. Quality Japanese carpentry and joinery tools are available in Amazon outlets.