Moisture meters are important tools of the trade for woodworkers, flooring contractors, and building inspectors. However, these tools come in two distinct styles: Pin vs. Pinless Moisture Meter. People are often confronted with a dilemma on which of the two is a better addition to their tool belts.

Here is a detailed evaluation of these two styles to help you determine the best fit for your intended use.

What is a Moisture Meter?

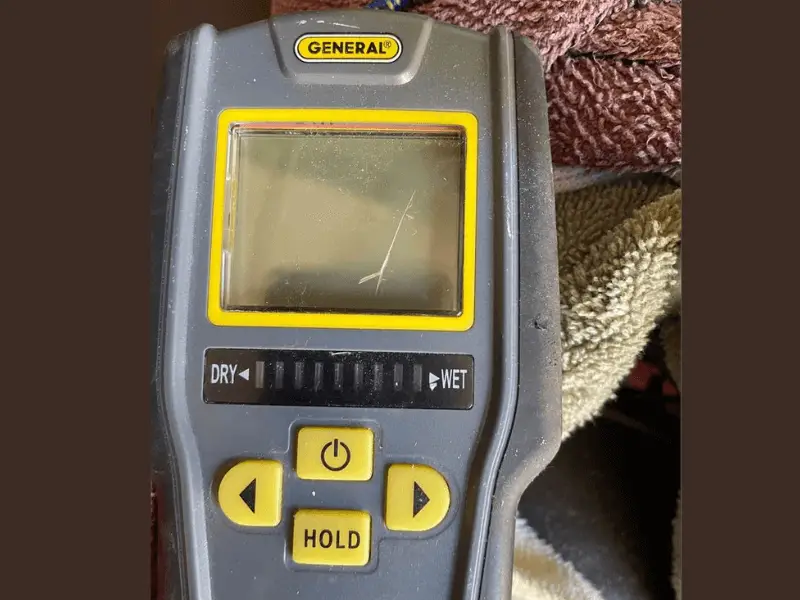

A moisture meter is a construction instrument used to measure a material’s moisture. It provides information regarding the percentage of water in any substance to determine its readiness, whether it is unusually wet or dry, or establish whether further investigation is needed.

Flooring contractors utilize moisture meters to determine ideal conditions in concrete slabs for floor installations. Similarly, woodworkers use this instrument to ascertain moisture content in wood, thus assessing the material’s quality. It is also commonly used by building inspectors to identify points of damage to a structure as indicated by the amount of moisture build-up.

How a Pinless Moisture Meter Works

The underlying technology in a pinless moisture meter is its electromagnetic sensor pad. To take a moisture content reading, the sensor pad comes into contact with the test surface, after which it produces electromagnetic signals.

This technology is founded on the principle of electrical impedance, whereby a combination of reactance and resistance effects within a circuit produces alternating currents. Its %MC readings are presented on a relative scale of 0-100 for wood and non-wood surfaces. Thanks to its non-invasive measuring technique, which cannot damage delicate surfaces, the pinless moisture meter is better suited for measuring wood and substrates like gypsum.

How a Pin Moisture Meter Works

On the contrary, a pin-type moisture meter has two pins that need to penetrate the test surface for an accurate measurement. %MC readings can only be produced after the un-insulated pins’ heads are fully immersed into the test surface. This technology is founded on the principle of electrical resistance, whereby the level of conductivity between the two pins determines the %MC. A pin-type meter can read up to a depth of 5/16 inches.

Unlike the pinless model, which measures a wide test surface, the pin-type meter is better suited to identify moisture build-up at specific locations. Since only the pins come into contact with the surface, this instrument is limited to assessing moisture content at the point of contact.

Factors to Consider When Choosing a Moisture Meter

To choose the ideal moisture meter for your project, you need to factor in the clear-cut differences in functionality between the pin-type and pinless variety.

An essential aspect to consider is surface damage. The pinless moisture meter is more fitting for mushy surfaces such as gypsum as it does not leave a mark. A pin-type moisture meter is guaranteed to leave a mark, albeit small, as its pins must come into contact with the text surface.

Speed is another factor of utmost importance. With the pinless unit, you can swiftly take multiple readings at different sites since you will not have to spend time lodging probes into the test surface. Therefore, inspectors can cover a vast area in a short time.

However, the pin-type model is more ideal for zeroing in on the exact source of moisture build-up due to its pinpoint accuracy. You should note that pin-type moisture meters detect the actual moisture content of a specific site.

On the flip side, although pinless meters measure the moisture content of vast areas through repeated readings, they cannot help you locate the actual point of moisture build-up. You should start by using the pinless meter to identify an area of moisture build-up and then use the pin-type meter to pinpoint the exact source of the build-up.

Does Surface Moisture Affect Moisture Meters?

Different types of moisture meters are affected differently by surface moisture. Although to a small degree, pinless moisture meters are negatively impacted by surface moisture. These tools can detect the amount of moisture on the test surface, which affects the eventual %MC reading. For instance, a pinless moisture meter will detect condensation on wood as moisture, reflecting the %MC as an additional 10% to 20%.

The pin-type meter is less prone to this problem. Those insulated pins at least 1.25 inches long are fully protected from surface moisture. However, pin-type meters with shorter shafts, especially the un-insulated kind, are likely to detect some surface moisture.

What is Relative Measurement Mode?

Relative measuring mode is a system used to determine approximate %MC readings instead of absolute readings. It is typically used to measure moisture content in non-solid surfaces such as gypsum panels.

Under this mode, moisture meters provide you with relative measurements by comparing different sections to an area of standard dryness. For such measurements, users establish a dry section that will serve as the baseline. You will then scan the rest of the surface to determine whether there are sections with higher %MC readings.

Conclusion

Despite their differences in functionality, pin-type and pinless moisture meters are both useful in moisture surveys. The pin-type meter is ideal for providing accurate %MC readings used to identify specific locations of moisture build-up.

At the same time, the pinless unit is designed to provide a representative assessment of wide surfaces. Given these unique attributes, having both varieties in your toolbox is prudent as one complements the other.

Check out our article on the best wood moisture meter as well.