When it comes to wood carving, the right oil finish can make all the difference in the world. There are a variety of oil finishes available that you can use to create a smooth, glossy finish on your wood carving projects. This blog post will discuss the best oil finishes for wood carving and their pros and cons. Whether an experienced carver or a beginner, you’ll learn what oil finish best suits your next project.

Best Oil Finishes for Wood Carving

Oil finishes are commonly believed to penetrate deep into the wood and protect it from the inside. The penetration occurs using capillary action. However, this does not imply that the penetration qualities of these finishes are the most important in protecting the wood; the only advantage gained by using this type of finish in your wood is to stabilize the wood against expansion and contraction caused by moisture exchange.

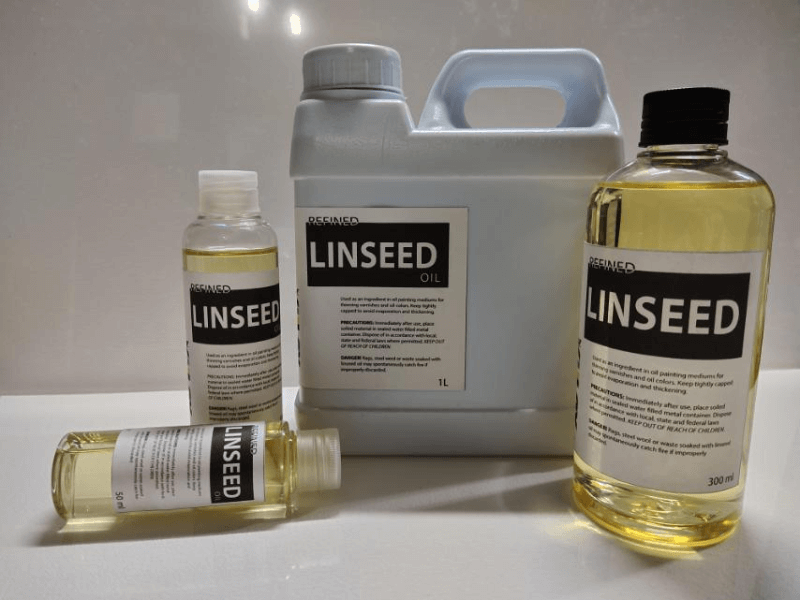

Linseed oil

If you want to create a simple finish, linseed oil is your best option. It comes from flax seeds, which are high in polyunsaturated fatty acids (PUFAs).

Linseed oil comes in a raw or boiled state. The oil in its raw form is insufficient as it takes longer to cure. As a result, metallic dries, which are usually salts of cobalt, zinc, or manganese, are added as catalysts to shorten the curing time. The linseed oil with metallic dries is commonly referred to as boiled linseed oil. It cures in about half a day, whereas raw linseed oil takes much longer to dry.

The boiled Linseed oil penetrates wood quickly and dries faster than most oils and varnishes.

Pros of Linseed Oil

- It’s odorless,

- It is tasteless,

- It is a good alternative if you want to avoid chemicals or need more experience working with solvents.

Cons of BLO

- The downside of linseed oil is its soft, thin finish; therefore, it doesn’t protect against UV rays or other finishes.

- It is also easily penetrated by water and water vapour.

However, it is easy to apply and allows the natural wood colours to come out well. You can find linseed oil at hardware stores, home improvement stores, and even some grocery stores.

The price will vary depending on where you buy it, but expect to pay about $10 per quart. The Best Boiled linseed oil to use that penetrates deep into the grain to help condition the wood, restore the wood, and ensure the longevity of your wood carving is the LinSheen Boiled Linseed Oil found on Amazon.

Tung Oil

While linseed oil is an excellent protective coating, some woodworkers prefer tung oil.

Although tung oil is more expensive than linseed oil, many woodcarvers choose to use it since it is one of the most water-resistant oil finishes compared to linseed oil. You’ll also learn that tung oil is a primary ingredient in quality varnishes.

Another benefit of using tung oil over linseed oil is that it doesn’t yellow as much as linseed oil, which is crucial when using it on blonde wood when you don’t want it to darken too much.

Nevertheless, while being one of the finest oils for water resistance, you must apply at least 5–6 coats. It is too soft and thin to withstand scratching or water vapour exchange.

If you use at most six coats, the finish will look patchy and flat on the wood and will be harsh to the touch. Unless you apply 5-6 layers with sanding in between, your carving will not have an even glossy surface. However, linseed oil will feel more smooth to the touch.

However, we can’t dismiss tung oil just yet because it’s so simple to use: with only a few drops, I rub it in with my thumb and fingers for a few minutes, and it brings out the colours in the wood just like I want. Then I wipe away the excess with a clean cloth (an old, washed T-shirt) and admire my job.

Danish Oil

Unlike linseed and tung oil, danish oil is a mixture of two or more oils. Usually, either tung oil or boiled linseed oil is used to make Danish oil. A solvent liquid is then added to thin the oils, making them easier to apply. You can also combine Danish oil with varnish, such as polyurethane, to boost and improve the oil’s resistance to dirt and stains. This increases its durability and gives it a smooth feel.

The finish of Danish oil is smoother and more polished; it is neither shiny nor sticky. It offers a tough finish that gives your carvings protection and durability. Furthermore, the finish helps to prevent water damage to the wood. It is simple to apply, dries quickly, and provides adequate protection while allowing the inherent grain and beauty of the wood to shine through.

Mineral oil

Mineral oil is an excellent choice for finishing wood carvings. It is easy to apply and gives the wood a soft finish, providing a subtle shine. Mineral oil is also very safe to use and won’t cause any harm to you or your woodwork.

Mineral oil is also relatively inexpensive compared to other wood finishing products. You can buy it in liquid form, or you can purchase solid mineral oil in paste form.

Importance of finishing wood carving

Finishing wood is a step that some woodworkers enjoy, and it is, of course, necessary. It is the definitive treatment of a carving’s surface after all tool work or sanding has been completed. Usually, a finish is meant to protect your wood from external factors.

There are three primary reasons why finishing your carving is critical:

- It helps keep your carving clean-Wood is a porous material by nature, making it susceptible to the accumulation of dirt and grime from handling or from atmospheric contaminants. However, a good finish can seal the porous surface, making it less sensitive to pollutants and thus keeping your carvings clean.

- It helps keeps the carving more Stable- In addition to being absorbent, wood is hygroscopy, which means it readily absorbs moisture from the environment. As a result, the wood will expand as soon as it begins to collect water from the air, and when it is placed in a relatively dry environment, it will release moisture and contract. The effects of this different response in the wood will result in a high stress in the wood, which will weaken it and cause splitting and warping. As a result, finishing the wood will reduce stress and stabilize the wood by slowing moisture transfers.

- Finishing is also a great way of decorating your carving.

How Do I Choose a Finish?

Factors to consider before choosing a finish

Before starting any wood carving project, choose a finish that will protect your hard work and make it last. There are a lot of finishes out there, and each has its purpose and benefits. To ensure that your wood carving looks perfect and lasts longer than the lifetime of the tree it came from, pay close attention to these tips on choosing the best finish for wood carvings.

Type of wood you will be using.

Different oils will react differently with different types of wood, so it’s essential to make sure you choose an oil that is compatible with your project.

For example, softwoods absorb oil-based finishes better than hardwoods, making them look nicer when finished with an oil-based product. Harder woods, on the other hand, require more coats of finish, or they will feel rough and unfinished.

If you’re working with pine, there are better options than linseed oil; it works well on harder woods like oak but not so much on pine. If you’re working with oak, however, linseed oil might be what you need—it gives a nice sheen that looks great against its dark colouration. Of course, each piece of wood is unique, so test out a few options before committing to one particular finish. Once you find something that works for you, use it consistently and treat every piece equally.

Desired level of protection

Some oils offer more excellent protection than others, so consider this when making your choice. For instance, tung and Danish oil protect wood against water and stains, while boiled linseed oil offers more of a natural look.

The appearance of the finished product

Oils can create different looks, such as a glossy or matte finish. If you’re looking for a more natural look, you may opt for oil like boiled linseed or tung oil.

Ease Of Maintenance

The ideal oil finish should be relatively easy to reapply and provide protection against environmental damage.

Danish oil is straightforward to maintain and has excellent protective properties. It can be easily reapplied with a soft cloth and will provide excellent protection against moisture, humidity, and temperature changes.

Mineral oil is one of the most accessible finishes to maintain. It only needs to be applied sometimes and does not require special tools or techniques.

Boiled linseed oil is also relatively easy to maintain, but it needs to be reapplied more frequently than other finishes. You will also need to use special tools and techniques for its application.

Finally, Tung oil is one of the most durable finishes but is a bit more challenging to maintain. It must be applied very carefully and will require frequent reapplication to maintain its protective qualities.

Conclusions

There is no definitive answer to finding the best oil finish for wood carving. Different types of oils can have other effects on different woods, so experimentation and research are necessary before deciding which oil finish will work best for your project.

Each of these oils offers unique advantages and drawbacks, and it is essential to understand their differences before deciding. Ultimately, the best oil finish for your wood carving project will depend on the type of wood, the desired outcome, and your preferences.

Best wood and oil for carving that has strength against breakage of tiny branches?